silver for smelting

Silver for Smelting Key Considerations and Techniques

Silver for smelting is an important aspect of the precious metal refining process. Smelting is a method used to extract silver from ores or scrap materials by heating and melting the material to separate impurities from the pure metal. This article explores the considerations for using silver in smelting, the techniques involved, and the benefits of effectively refining silver.

Understanding Silver for Smelting

Silver for smelting typically refers to raw silver or silver-containing materials that are processed to achieve a high level of purity. This can include silver ore extracted from mines, scrap silver from old jewelry or electronics, or silver alloys. The primary goal of smelting is to separate the pure silver from other elements and impurities, producing silver that meets industry standards for various applications.

Types of Silver Materials for Smelting

Silver Ore

Silver ore is the naturally occurring form of silver found in the earth. It is often mixed with other minerals and metals, making it necessary to use smelting techniques to extract the pure silver. Silver ore requires initial processing, such as crushing and grinding, to prepare it for smelting.

Scrap Silver

Scrap silver includes items like old jewelry, coins, or silverware that contain silver but are no longer in use. Scrap silver can be a valuable source of material for smelting, as it often contains high concentrations of silver. However, it may also include other metals and alloys, which need to be separated during the smelting process.

Silver Alloys

Silver alloys are mixtures of silver with other metals, such as copper or nickel. These alloys are often used in industrial applications or jewelry. Smelting silver alloys requires careful management of the alloying elements to ensure the final product meets purity standards.

Techniques for Smelting Silver

Traditional Smelting

Traditional smelting involves heating silver ore or scrap in a furnace to high temperatures, typically between 1,200 and 1,500 degrees Celsius (2,192 to 2,732 degrees Fahrenheit). Fluxes, such as borax or soda ash, are added to help remove impurities and lower the melting point of the silver. The molten silver is then poured into molds and allowed to cool.

Fire Assay

Fire assay is a highly accurate method used to determine the purity of silver. It involves heating a sample with fluxes in a high-temperature furnace, separating the silver from other elements, and measuring the purity of the resulting metal. This technique is often used for testing the quality of silver before and after smelting.

Electrolytic Refining

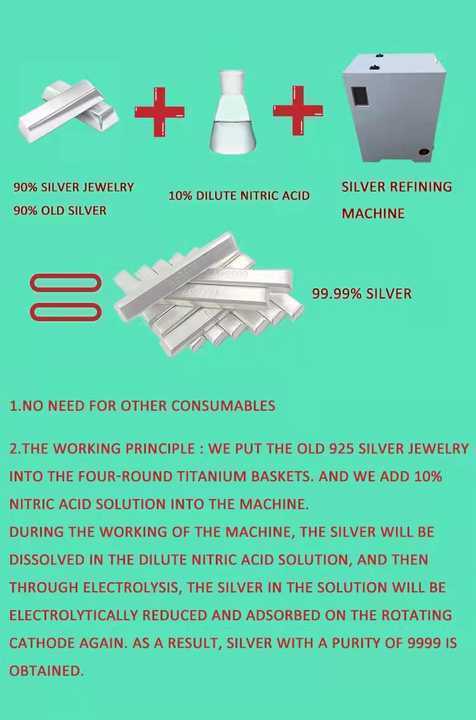

Electrolytic refining is a process that uses an electrolytic cell to purify silver. In this method, silver is dissolved in an electrolyte solution and then redeposited onto a cathode in a pure form. Electrolytic refining is particularly useful for achieving very high purity levels and is commonly used in industrial settings.

Chemical Refining

Chemical refining involves using chemicals to separate silver from impurities. This method includes the use of acids or other reagents that react with unwanted elements, leaving behind pure silver. Chemical refining can be used in combination with other smelting techniques to enhance the purity of the final product.

Benefits of Smelting Silver

Increased Purity

One of the primary benefits of smelting silver is the ability to produce high-purity metal. Smelting removes impurities and other elements, resulting in silver that meets industry standards for various applications, including jewelry, electronics, and investment.

Recycling and Resource Conservation

Smelting silver from scrap materials and ores helps in recycling valuable metals and conserving natural resources. By reusing silver from old items and reducing the need for new mining operations, smelting contributes to a more sustainable approach to metal production.

Enhanced Value

Refined silver has a higher market value compared to unrefined silver. Effective smelting ensures that the silver produced is of high quality, which can result in better financial returns for refiners and sellers.

Considerations for Smelting Silver

Equipment Selection

Choosing the right equipment for smelting silver is essential for achieving optimal results. This includes selecting appropriate furnaces, crucibles, and fluxes based on the type of silver material being processed and the scale of the operation.

Temperature Control

Accurate temperature control is crucial for successful smelting. Proper management of temperatures ensures that the silver melts effectively and that impurities are removed efficiently.

Safety Measures

Safety is a critical consideration in the smelting process. Proper protective gear, such as gloves, safety glasses, and face shields, should be used to protect against high temperatures and molten metal. Adequate ventilation and handling procedures should also be in place to ensure a safe working environment.

Silver for smelting encompasses a range of materials, including ore, scrap, and alloys, each requiring specific techniques to achieve high purity. By understanding the methods and benefits of smelting silver, refiners can effectively process silver to meet industry standards and enhance its value. Whether for jewelry, electronics, or other applications, proper smelting techniques contribute to the successful refinement and use of this valuable metal.