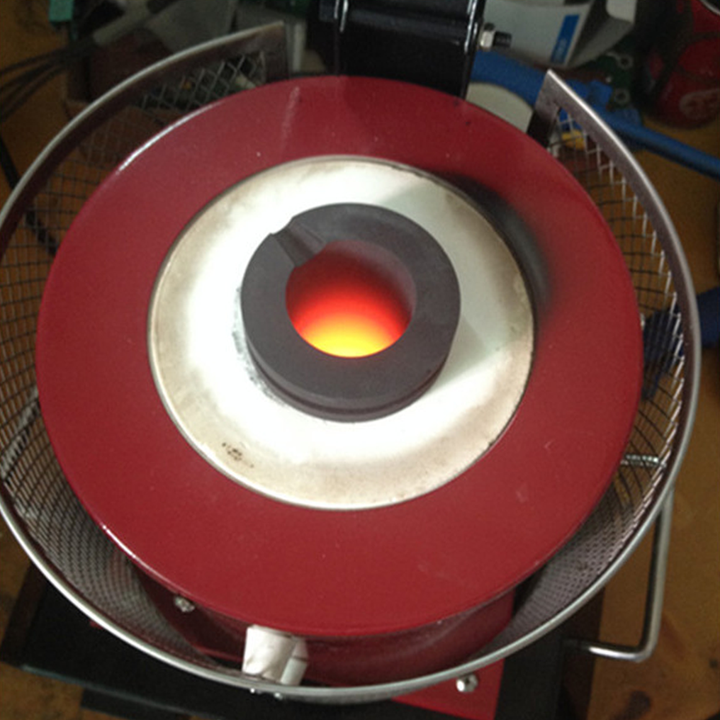

silver smelting furnace

Silver Smelting Furnace Essential Equipment for Efficient Silver Refining

A silver smelting furnace is a critical piece of equipment in the precious metals industry, designed to extract silver from ores, scrap materials, or other silver-containing substances. The furnace heats the material to high temperatures, enabling the separation of silver from impurities. This article explores the key aspects of silver smelting furnaces, including their types, functions, benefits, and considerations for effective operation.

Understanding Silver Smelting Furnaces

Silver smelting furnaces are used to melt and refine silver by applying intense heat. The primary objective is to achieve high-purity silver by removing impurities and separating valuable silver from other elements. The furnace plays a crucial role in this process, making it essential to choose the right type and model based on specific needs and applications.

Types of Silver Smelting Furnaces

Several types of smelting furnaces are used in the silver refining process, each offering unique features and benefits:

Electric Furnaces

Electric furnaces use electric heating elements to achieve precise temperature control. They are commonly used in small to medium-scale smelting operations and offer several advantages:

- Precise Temperature Control: Allows for accurate adjustment of heat levels, crucial for achieving optimal refining results.

- Energy Efficiency: Generally more energy-efficient compared to other types of furnaces, reducing operational costs.

- Reduced Emissions: Electric furnaces produce fewer emissions, making them environmentally friendly.

Gas Furnaces

Gas furnaces use gas burners to heat the silver-containing material. They are suitable for larger-scale smelting operations and provide high heating capacity:

- High Heating Capacity: Capable of handling larger quantities of material, making them ideal for industrial-scale operations.

- Cost-Effective: Gas furnaces can be more cost-effective in terms of energy consumption compared to electric models.

Induction Furnaces

Induction furnaces utilize electromagnetic induction to heat the material. Known for their efficiency and precision, induction furnaces offer several benefits:

- Rapid Heating: Provides quick heating times, improving overall processing efficiency.

- Uniform Heating: Ensures even heating of the material, reducing the risk of uneven melting and contamination.

- Energy Efficiency: Highly efficient in energy use, which can lower operational costs over time.

Key Features and Components

Silver smelting furnaces come equipped with various features and components designed to enhance performance and efficiency:

Crucibles

Crucibles are containers used to hold the silver material during the smelting process. They must withstand high temperatures and corrosive conditions. Common types include:

- Graphite Crucibles: Known for their excellent thermal conductivity and durability.

- Clay Graphite Crucibles: Provide a balance between cost and performance.

Temperature Control Systems

Advanced temperature control systems allow for precise management of heat levels, which is crucial for achieving high-quality results. Features may include:

- Digital Controllers: Provide accurate temperature readings and allow for fine-tuning of heat levels.

- Safety Alarms: Alert operators to any temperature deviations or malfunctions.

Cooling Systems

Cooling systems are essential for managing the temperature of the furnace and ensuring safe operation. They include:

- Water-Cooling Systems: Use water to absorb and dissipate heat from the furnace and other components.

- Air-Cooling Systems: Utilize fans and ventilation to maintain safe operating temperatures.

Benefits of Using a Silver Smelting Furnace

Investing in a high-quality silver smelting furnace offers several advantages:

Enhanced Efficiency

A well-designed furnace ensures efficient heating and melting of silver-containing materials. This leads to faster processing times and better recovery of silver.

Improved Purity

Precise temperature control and uniform heating contribute to higher purity levels of the refined silver. This is essential for producing silver that meets industry standards and customer requirements.

Safety and Environmental Benefits

Modern furnaces often include safety features such as automatic shut-offs and advanced cooling systems. Additionally, electric and induction furnaces produce fewer emissions, supporting environmentally responsible practices.

Considerations for Choosing a Silver Smelting Furnace

When selecting a silver smelting furnace, consider the following factors:

Scale of Operation

- Small-Scale Operations: Electric furnaces and smaller induction models are suitable for smaller smelting tasks and provide precise control.

- Large-Scale Operations: Gas furnaces or larger induction furnaces are better suited for handling large quantities of material.

Budget and Costs

- Initial Investment: Evaluate the cost of purchasing and installing the furnace. Higher upfront costs may be justified by improved performance and efficiency.

- Operating Costs: Consider the ongoing costs of energy consumption, maintenance, and replacement parts.

Technological Features

- Automation: Look for furnaces with automated controls and monitoring systems for improved precision and reduced manual intervention.

- Energy Efficiency: Choose models designed to optimize energy use and reduce operational expenses.

A silver smelting furnace is a vital piece of equipment in the silver refining process, crucial for achieving high-purity silver and efficient operation. By understanding the different types of furnaces, key features, and benefits, operators can make informed decisions and select the equipment best suited to their needs. Investing in a high-quality smelting furnace enhances efficiency, improves silver purity, and supports safe and environmentally responsible practices in the precious metals industry.