Small Scale Gold Refining

Small Scale Gold Refining: A Comprehensive Guide

Gold refining is a critical process in the extraction of pure gold from raw materials. This guide explores the intricacies of small scale gold refining, focusing on methods, benefits, and technologies that can be employed by individuals or small operations to achieve high purity levels. Whether you’re a hobbyist or a small business owner, understanding these processes can significantly enhance your ability to produce valuable, refined gold.

Small Scale Gold Refining Techniques

There are several techniques used for small scale gold refining, each with its own set of advantages and disadvantages. Among the most common are fire assay, electrolytic refining, and chemical leaching. Fire assay involves heating the ore to a high temperature to burn off impurities, leaving behind a concentrated gold button. Electrolytic refining uses electric current to separate gold from other metals, while chemical leaching utilizes solutions like cyanide to dissolve gold, making it easier to extract. Each method requires specialized equipment, such as furnaces, electrodes, and chemical tanks, which can be sourced from suppliers likeFRT Machinery.

Benefits of Small Scale Gold Refining

The benefits of engaging in small scale gold refining are numerous and significant. Firstly, it allows for greater control over the refining process, ensuring higher purity levels and better quality control. Secondly, it can be more cost-effective than large-scale operations, especially when considering the initial investment and ongoing operational costs. Lastly, small scale refining can be environmentally friendlier, particularly if sustainable practices are implemented.FRT Machineryoffers a range of solutions designed specifically for small scale operations, ensuring efficiency and sustainability.

Equipment Needed for Small Scale Gold Refining

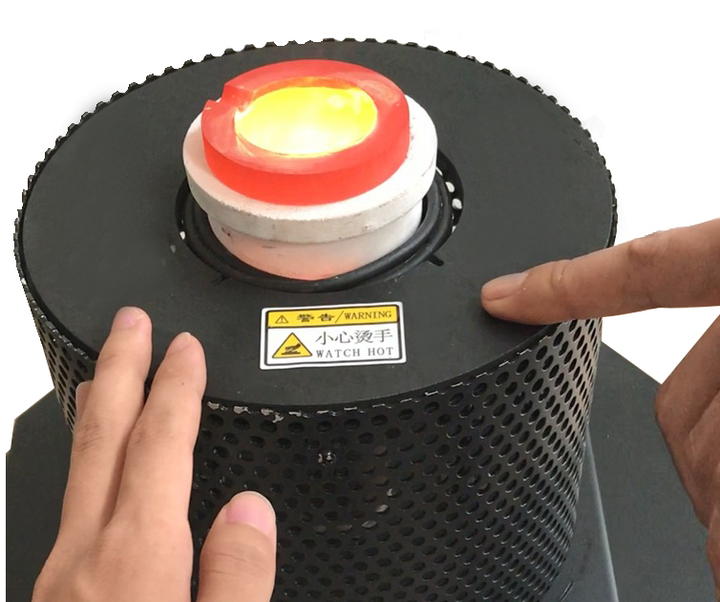

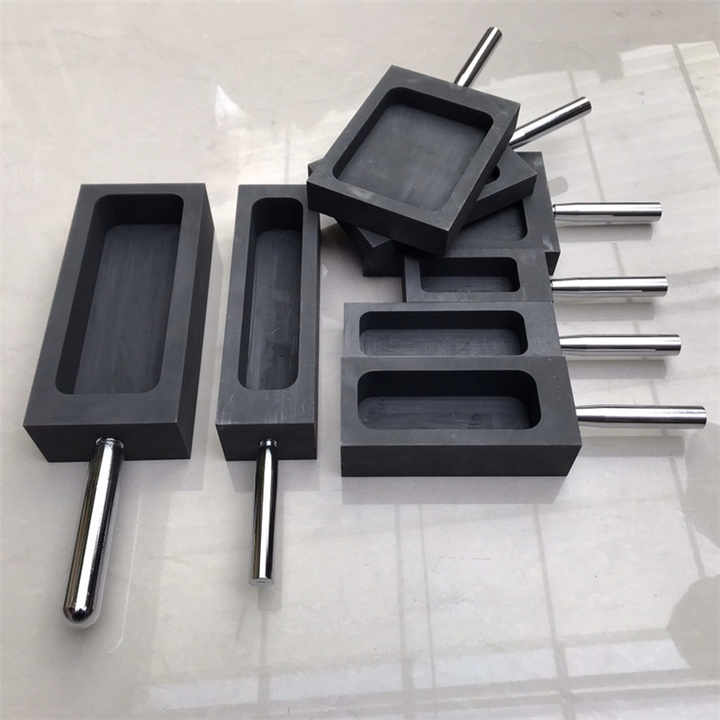

To start a small scale gold refining operation, certain pieces of equipment are essential. These include crucibles, melting furnaces, refining tanks, and testing kits. Crucibles are used to hold the material during the heating process, while melting furnaces provide the necessary heat to melt the gold. Refining tanks are used in electrolytic refining, where the gold is separated from impurities using an electric current. Testing kits help verify the purity of the gold post-refining.FRT Machineryprovides all these tools, tailored to meet the needs of small scale refiners, ensuring both safety and efficiency.

Environmental Considerations in Small Scale Gold Refining

One of the major concerns in gold refining, especially on a small scale, is the environmental impact. Chemicals like mercury and cyanide, commonly used in refining processes, can be harmful if not handled properly. Therefore, it’s crucial to adopt eco-friendly alternatives and best practices. For instance, using closed-loop systems to prevent chemical leakage and implementing recycling programs for waste materials can significantly reduce the environmental footprint.FRT Machinerysupports these initiatives by offering equipment that complies with environmental standards, helping refiners maintain a green operation.

Training and Safety Measures for Small Scale Gold Refining

Safety should always be a top priority in any refining operation. Proper training and adherence to safety protocols are vital to prevent accidents and ensure a healthy work environment. This includes wearing protective gear, handling chemicals safely, and maintaining equipment regularly.FRT Machinerynot only supplies the necessary equipment but also provides comprehensive training programs to ensure users understand how to operate their machinery safely and effectively.

Future Trends in Small Scale Gold Refining

As technology advances, so do the methods and tools used in small scale gold refining. Innovations in automation, robotics, and artificial intelligence are gradually being integrated into refining processes, improving efficiency and reducing labor costs. Additionally, there is a growing trend towards modular and mobile refining units, which offer flexibility and ease of setup.FRT Machineryis at the forefront of these developments, continuously updating its product line to reflect these trends and support the evolving needs of small scale refiners.

By embracing modern techniques and technologies, small scale gold refining can become a highly profitable venture, capable of producing high-quality gold products efficiently and responsibly. Whether you’re just starting out or looking to upgrade your existing operation,FRT Machineryis here to provide the right solutions for your needs.