Smelting Flour Gold

Smelting Flour Gold: A Comprehensive Guide

Flour gold, due to its fine nature, poses unique challenges when it comes to smelting. This form of gold, characterized by particles so small they resemble flour, requires specialized techniques and equipment to effectively process and recover. In this guide, brought to you by FRT Machinery, we explore the intricacies of smelting flour gold, providing insights into the best practices, necessary equipment, and potential pitfalls to avoid.

Preparing for Smelting Flour Gold

Before diving into the smelting process, preparation is key. This involves several steps designed to ensure that the flour gold is ready for smelting. First, it’s crucial to clean the gold thoroughly to remove any contaminants that could interfere with the smelting process. Using specialized cleaning agents and techniques, such as ultrasonic baths, can help achieve this goal efficiently.

Once cleaned, the next step is to dry the flour gold completely. Moisture can cause issues during smelting, leading to poor quality ingots or even dangerous explosions if water comes into contact with molten gold. Employing industrial drying equipment from FRT Machinery ensures that all moisture is removed without damaging the delicate gold particles.

Equipment for Smelting Flour Gold

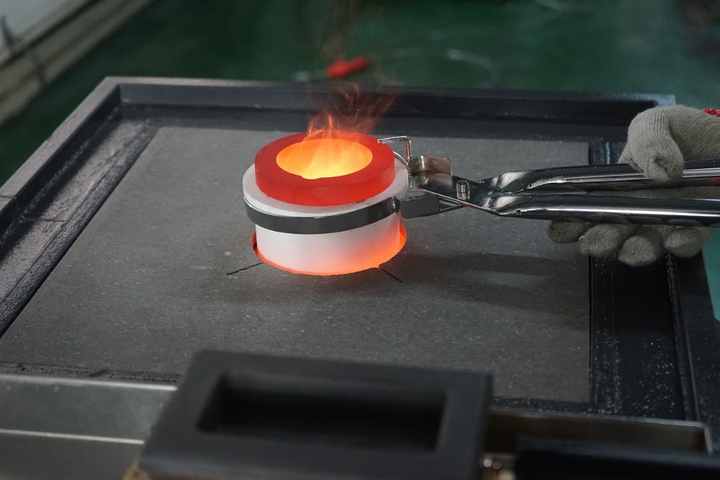

The right equipment is essential for successful smelting of flour gold. FRT Machinery offers a range of solutions specifically designed for this purpose. Crucibles, furnaces, and melting pots must be capable of reaching and maintaining high temperatures while also being resistant to corrosion from the molten metal.

Furnaces used for smelting flour gold need to be equipped with precise temperature control systems. This allows operators to maintain the optimal temperature throughout the smelting process, ensuring that the gold melts evenly and without overheating. Additionally, using a vacuum or inert gas environment within the furnace helps protect the gold from oxidation, preserving its purity.

Techniques for Smelting Flour Gold

Smelting flour gold requires careful attention to detail and adherence to specific techniques. One effective method involves preheating the gold particles gradually to prevent thermal shock. Gradual heating ensures that the gold melts smoothly, reducing the risk of agglomeration or clumping, which can occur with rapid heating due to the small size of the particles.

Another technique is to add fluxes during the smelting process. Fluxes help separate impurities from the gold, making it easier to refine the final product. Common flux materials include borax and silica, which lower the melting point of slag, allowing it to be easily removed from the molten gold.

Safety Considerations When Smelting Flour Gold

Safety should always be a top priority when working with high-temperature processes like smelting. Proper protective gear, including heat-resistant gloves, face shields, and respirators, is a must. Ventilation is also critical; fumes released during smelting can be harmful if inhaled. Installing a robust ventilation system in your workspace will help mitigate this risk.

Moreover, having fire extinguishers and other safety equipment readily available is essential. Regular training on emergency procedures ensures that everyone involved knows what to do in case of accidents, further enhancing workplace safety.

Post-Smelting Processing of Flour Gold

After smelting, the gold needs to be cooled and cast into desired shapes. Cooling too quickly can result in structural defects within the ingot, whereas slow cooling might lead to uneven hardness across the piece. Controlled cooling environments provided by FRT Machinery’s cooling chambers help maintain uniform cooling rates, ensuring the integrity of the final product.

Once cooled, the gold can be further refined or alloyed depending on the intended application. Quality checks at this stage are important to verify the purity and consistency of the smelted gold, ensuring it meets industry standards.

Conclusion

Smelting flour gold is a complex process that demands precision and expertise. By following these guidelines and utilizing state-of-the-art equipment from FRT Machinery, you can optimize your smelting operations, achieving higher yields and superior quality products. Whether you’re just starting out or looking to upgrade your existing setup, investing in the right tools and techniques will set you up for success in the challenging yet rewarding world of flour gold smelting.