smelting gold dust

Smelting Gold Dust Techniques and Considerations for High-Quality Gold Production

Smelting gold dust is a critical process in the gold refining industry, essential for transforming fine gold dust into solid, high-purity gold bars or ingots. Gold dust, which consists of tiny particles of gold, requires a specific approach to ensure efficient smelting and recovery. This article explores the smelting process for gold dust, including key steps, benefits, and important considerations.

What is Gold Dust?

Gold dust refers to fine particles of gold that are often recovered from gold-bearing materials through various processes such as panning, sluicing, or shaking tables. Unlike larger gold nuggets or grains, gold dust is extremely fine and requires careful handling and processing to achieve high-quality results.

The Smelting Process for Gold Dust

1. Preparation of Gold Dust

Before smelting, gold dust needs to be properly prepared to ensure an effective smelting process:

- Concentration: If necessary, gold dust can be concentrated to remove non-gold materials and increase its purity. This may involve using gravity separation methods or chemical treatments.

- Mixing with Flux: Gold dust is mixed with flux materials such as borax or silica. These fluxes help to separate impurities from gold during the smelting process and form a slag that can be removed.

2. Loading the Furnace

The prepared gold dust is then loaded into a smelting furnace along with the flux materials:

- Furnace Selection: A suitable furnace for smelting gold dust could be a propane furnace, electric furnace, or other high-temperature melting equipment.

- Fuel: Depending on the type of furnace used, appropriate fuel or energy sources are selected to achieve the high temperatures required for melting gold dust.

3. Smelting Process

The actual smelting of gold dust involves several critical steps:

- Heating: The furnace is heated to temperatures between 1,000°C and 1,500°C (1,800°F to 2,700°F). Gold dust is introduced into the furnace along with the flux materials.

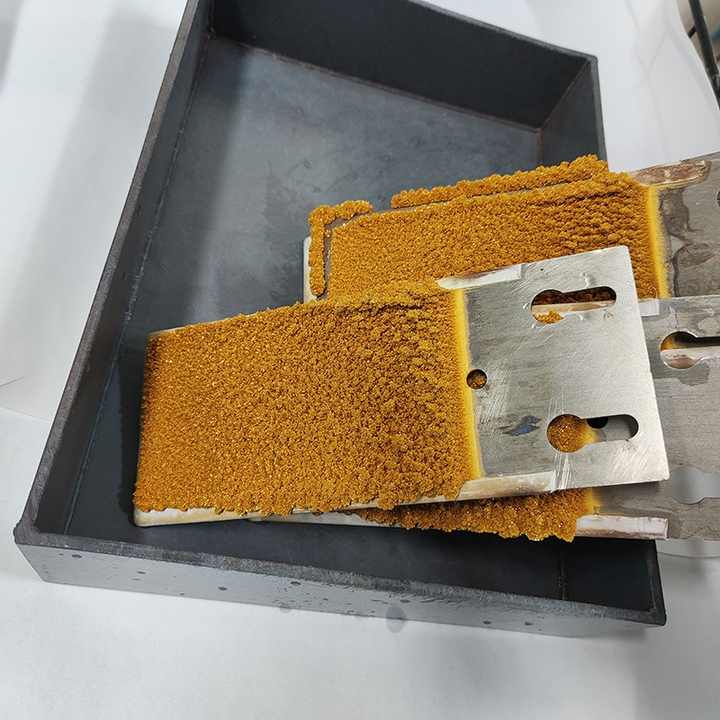

- Melting: As the temperature rises, the gold dust and flux materials melt. Gold, being denser, sinks to the bottom of the furnace, while impurities, including slag, float on top.

- Separation: The molten gold is separated from the slag. The slag is removed from the surface of the molten gold, leaving behind pure gold.

4. Post-Smelting Treatment

Once the smelting process is complete, the gold undergoes several post-treatment steps:

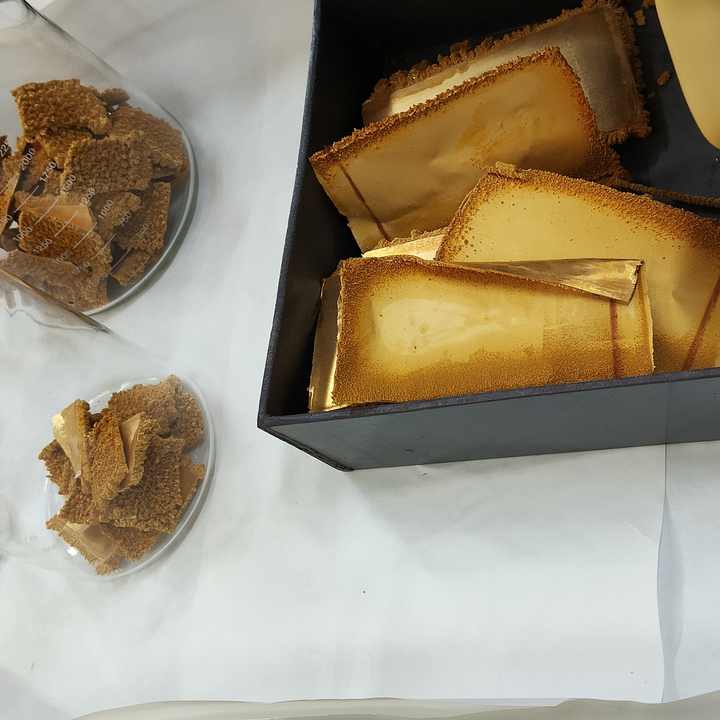

- Cooling and Solidifying: The molten gold is poured into molds to solidify into gold bars or ingots. Once cooled, the gold is removed from the molds and inspected for quality.

- Refining: Additional refining may be required to achieve the desired level of purity. This can involve chemical treatments or electrolytic refining processes.

Benefits of Smelting Gold Dust

Smelting gold dust offers several key benefits:

- High Purity: The smelting process effectively removes impurities and recovers high-purity gold from fine dust.

- Efficiency: Smelting is a practical method for processing fine gold dust and transforming it into solid gold bars or ingots.

- Value Recovery: The process maximizes the value recovery of gold dust by converting it into a more valuable and marketable form.

Considerations and Challenges

Smelting gold dust presents some challenges and considerations:

- Handling Fine Particles: Gold dust is very fine and can be challenging to handle. Proper techniques must be used to ensure efficient processing and minimize loss.

- Energy Consumption: High temperatures are required for smelting, which can result in significant energy consumption and associated costs.

- Environmental Impact: The smelting process generates emissions and waste that must be managed to minimize environmental impact.

Smelting gold dust is an essential process for transforming fine gold particles into high-purity gold bars or ingots. By preparing the gold dust, mixing it with flux materials, and carefully managing the smelting process, gold dust is effectively converted into valuable and marketable gold products. Despite the challenges associated with handling fine particles and the energy requirements, smelting remains a highly effective method for gold recovery and production. Understanding the smelting process for gold dust is crucial for achieving optimal results and ensuring high standards in gold refining.