smelting gold from electronics

Smelting Gold from Electronics A Comprehensive Guide

Smelting gold from electronics is an important process in the e-waste recycling industry. Electronics such as computers, smartphones, and circuit boards contain small amounts of gold, which can be recovered and refined. This article provides an overview of the smelting process for extracting gold from electronics, including key steps, benefits, and challenges.

What is Gold Recovery from Electronics?

Gold recovery from electronics involves extracting gold from electronic waste (e-waste) through various methods. Electronic devices often contain gold in the form of gold-plated connectors, circuit boards, and other components. The recovery process aims to separate gold from other materials and contaminants, transforming it into pure, usable gold.

The Smelting Process for Gold from Electronics

1. Preparation of Electronic Waste

Before smelting, electronic waste needs to be prepared to ensure an efficient extraction process:

- Disassembly: Electronic devices are disassembled to separate components containing gold, such as circuit boards and connectors.

- Shredding: The separated components are shredded into smaller pieces to facilitate further processing and increase surface area.

- Concentration: The shredded materials are concentrated to increase the proportion of gold relative to other materials. This can be achieved through methods like gravity separation, flotation, or chemical leaching.

2. Chemical Pre-Treatment

Prior to smelting, a chemical pre-treatment may be necessary to further prepare the gold-bearing materials:

- Leaching: Chemical leaching, often using cyanide or aqua regia, can dissolve gold from the electronic waste. This process separates gold from other metals and contaminants, resulting in a gold solution.

- Filtering: The gold solution is filtered to remove impurities and non-gold materials, leaving behind a concentrated gold solution.

3. Mixing with Flux

The prepared gold-bearing material is then mixed with fluxes to aid in the smelting process:

- Flux Materials: Fluxes such as borax, soda ash, or silica are added to help separate impurities from gold during smelting. Fluxes react with impurities to form a slag that can be removed.

- Ratio: The amount of flux used depends on the composition of the material and the desired outcome of the smelting process.

4. Loading the Furnace

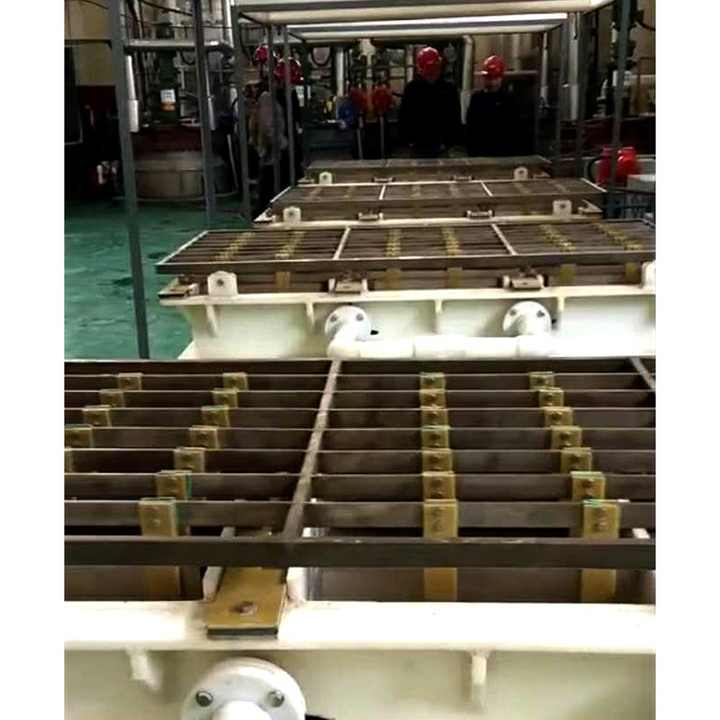

The mixture of gold-bearing material and flux is loaded into a smelting furnace:

- Furnace Selection: A suitable furnace for smelting gold from electronics could be a propane furnace, electric furnace, or induction furnace.

- Fuel: Depending on the furnace type, appropriate fuels or energy sources are selected to achieve the high temperatures required for smelting.

5. Smelting Process

The core of the smelting process involves several key steps:

- Heating: The furnace is heated to temperatures between 1,000°C and 1,500°C (1,800°F to 2,700°F). The gold-bearing material and flux are introduced into the furnace.

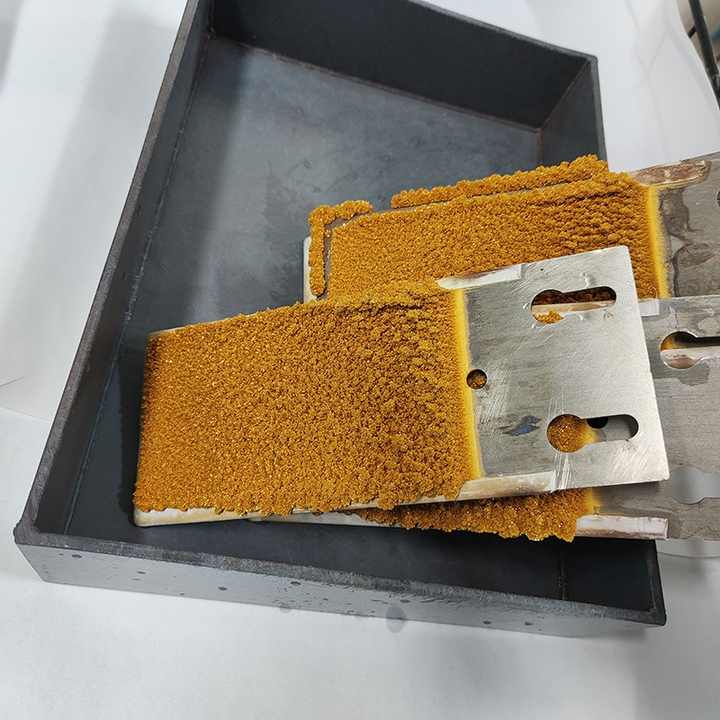

- Melting: As the temperature increases, the gold-bearing material and flux melt. Gold, being denser, sinks to the bottom of the furnace, while impurities and slag float on top.

- Separation: The molten gold is collected from the bottom of the furnace, while the slag is removed from the surface.

6. Post-Smelting Treatment

After smelting, the gold undergoes several additional steps:

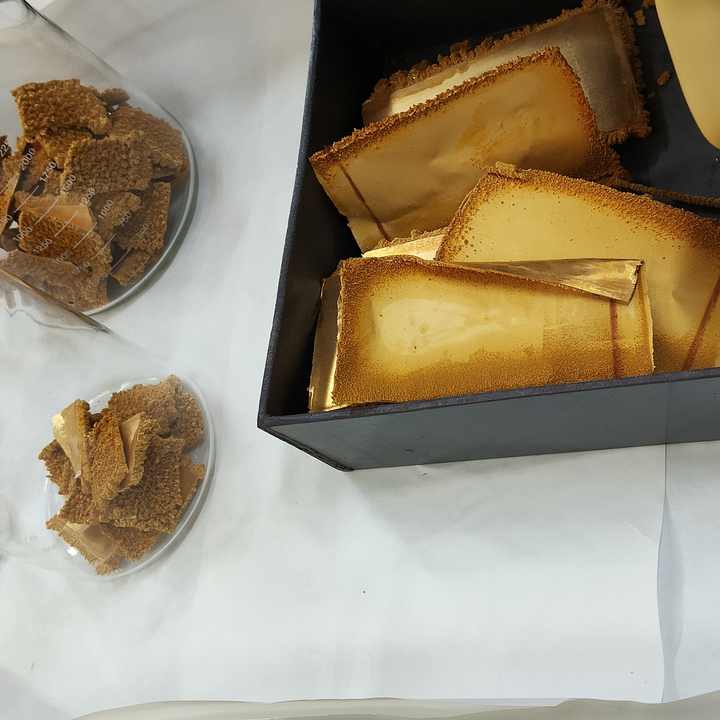

- Cooling and Solidifying: The molten gold is poured into molds to solidify into gold bars or ingots. Once cooled, the gold is inspected for quality and purity.

- Refining: Additional refining may be required to achieve the desired purity. This can include further chemical treatments or electrolytic refining processes.

Benefits of Smelting Gold from Electronics

Smelting gold from electronics offers several advantages:

- Resource Recovery: Smelting recovers valuable gold from electronic waste, reducing the need for new mining and conserving natural resources.

- Economic Value: Extracting gold from electronics can be economically beneficial, as gold is a valuable material.

- Environmental Impact: Proper recycling and smelting of e-waste help reduce environmental pollution associated with improper disposal.

Considerations and Challenges

Smelting gold from electronics also presents some challenges:

- Handling Hazardous Materials: Electronic waste often contains hazardous materials such as lead or mercury. Proper handling and disposal are required to ensure safety and environmental protection.

- Energy Consumption: High temperatures are required for smelting, which can result in significant energy consumption and associated costs.

- Complexity of Materials: Electronic waste can contain a wide variety of materials and contaminants, making the smelting process more complex and requiring precise control.

Smelting gold from electronics is a crucial process for recovering valuable gold from e-waste. By preparing electronic waste, applying chemical pre-treatments, mixing with fluxes, and carefully managing the smelting process, gold can be effectively extracted and refined. Despite challenges such as handling hazardous materials and energy consumption, smelting offers significant benefits in terms of resource recovery and environmental impact. Understanding the smelting process for gold from electronics is essential for optimizing gold recovery and maintaining high standards in e-waste recycling.