Smelting Gold Into Powder

Smelting Gold Into Powder: A Comprehensive Guide

Smelting gold into powder is a process that has been refined over centuries, blending ancient techniques with modern technology to produce high-quality gold powder used in various industries. This guide by FRT Machinery will walk you through the steps involved, the equipment required, and the best practices for smelting gold into powder efficiently and safely.

Preparing Gold Ore for Smelting

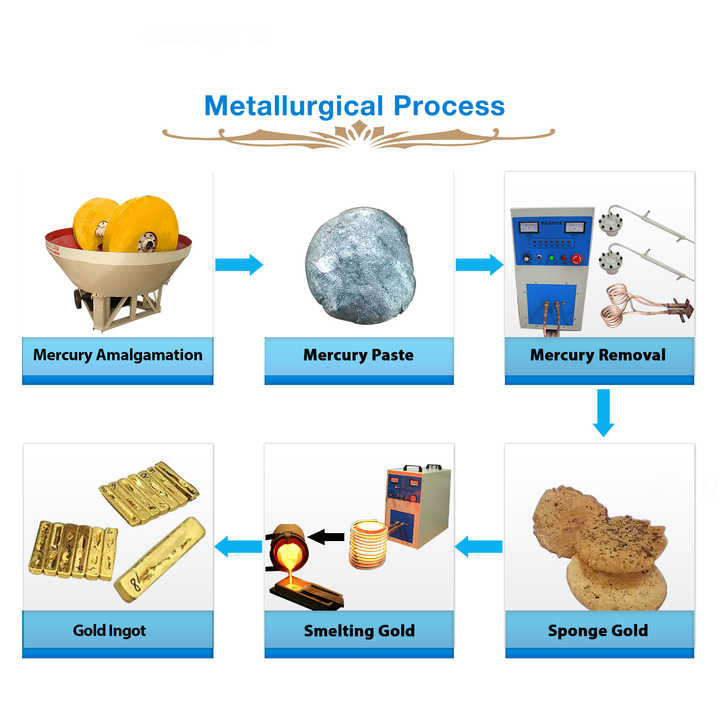

Before smelting gold into powder, it’s crucial to prepare the gold ore properly. This involves crushing and grinding the ore to reduce its size significantly. FRT Machinery offers state-of-the-art crushers and grinders designed specifically for gold ores. These machines ensure that the ore is reduced to particles small enough for efficient smelting. Once the ore is finely ground, it’s ready for the next step in the process—smelting.

Choosing the Right Smelting Equipment

Selecting appropriate equipment is vital when smelting gold into powder. FRT Machinery provides a range of smelters tailored for different scales of operation, from small-scale artisanal miners to large industrial complexes. Our smelters are equipped with advanced features such as temperature control systems and safety mechanisms, ensuring that the smelting process is both precise and secure.

The Smelting Process

The actual smelting process involves heating the prepared gold ore to extremely high temperatures, typically above 1,000 degrees Celsius, until it melts. At FRT Machinery, we recommend using our specialized gold smelters which maintain consistent heat levels necessary for melting gold without losing its purity. After melting, the liquid gold is then cooled and solidified, preparing it for further refinement into powder form.

Refining Liquid Gold to Powder

After smelting gold into a liquid state, refining it into powder requires additional steps. One common method is to use a ball mill or a similar device provided by FRT Machinery. These mills grind the solidified gold into fine particles, eventually producing gold powder. It’s important to adjust the milling time according to the desired particle size of the gold powder.

Ensuring Purity During the Smelting Process

Maintaining the purity of gold during the smelting process is essential for producing high-quality gold powder. FRT Machinery’s smelting equipment includes filtration systems that remove impurities from the melted gold, ensuring that only pure gold is processed into powder. Regular maintenance and cleaning of these systems are recommended to keep them functioning optimally.

Safety Measures When Smelting Gold Into Powder

Safety should always be a top priority when working with high-temperature processes like smelting gold into powder. FRT Machinery emphasizes the importance of wearing protective gear such as heat-resistant gloves, goggles, and aprons. Additionally, our smelters come equipped with safety features like emergency shut-off switches and alarms to prevent accidents during operation.

Sustainable Practices in Gold Smelting

As awareness grows regarding environmental sustainability, FRT Machinery is committed to developing more eco-friendly methods for smelting gold into powder. This includes using renewable energy sources to power our smelting equipment and designing machinery that reduces waste and emissions. By adopting these sustainable practices, we can contribute to a greener future while maintaining the quality standards expected in gold processing.

By following these guidelines and utilizing the right equipment from FRT Machinery, smelting gold into powder becomes a streamlined process that yields superior results. Whether you’re a seasoned professional or just starting in the gold processing industry, investing in reliable tools and adhering to best practices will ensure success in your endeavors.