Smelting Gold Items

Smelting Gold Items: A Comprehensive Guide to Mastering the Art

Smelting gold items is an ancient practice that has evolved significantly over the centuries. Today, thanks to advancements in technology and metallurgy, smelting gold has become more efficient and environmentally friendly. Whether you’re a seasoned professional or just starting out, understanding the intricacies of smelting gold can greatly enhance your ability to produce high-quality products. This guide will walk you through the essential steps and techniques for smelting gold items, ensuring a successful outcome every time.

Preparing Gold Items for Smelting

Before you begin the smelting process, it’s crucial to prepare your gold items properly. This involves cleaning them thoroughly to remove any dirt, oils, or other contaminants that could affect the purity of the melted gold. Using specialized cleaning solutions recommended by FRT Machinery, you can ensure that your gold pieces are ready for smelting. Additionally, sorting gold items by their karat value ensures that alloys of different purities are melted separately, maintaining the integrity of the final product.

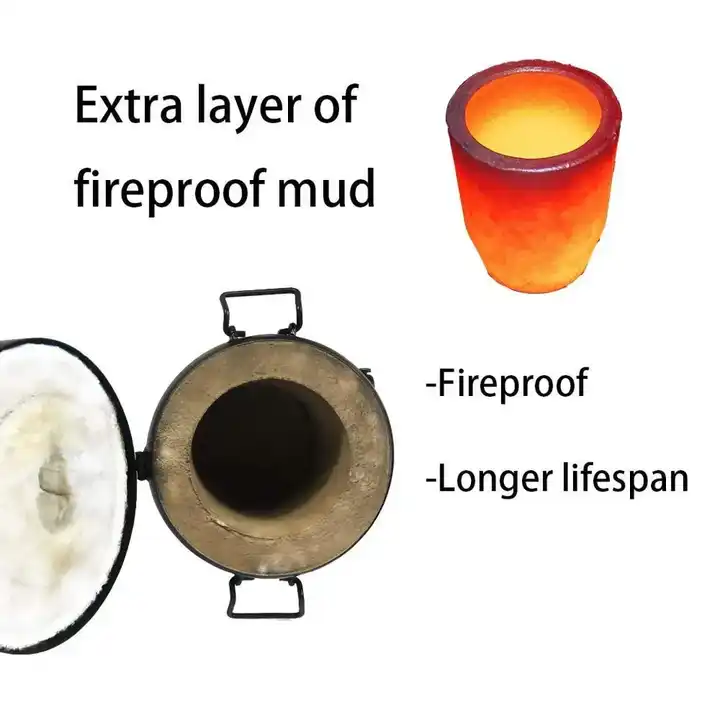

Selecting the Right Smelting Equipment

Choosing the appropriate equipment is key to successful smelting. FRT Machinery offers a range of furnaces designed specifically for smelting gold items. These furnaces provide precise temperature control, which is essential for achieving the optimal melting point of gold (around 1,948°F or 1,064°C). Investing in quality smelting equipment from FRT Machinery guarantees consistent results and minimizes the risk of overheating, which can lead to loss of material.

Understanding the Smelting Process

The smelting process itself involves heating gold items until they reach their melting point, allowing them to be poured into molds. However, it’s not just about reaching the right temperature; it’s also important to maintain a controlled environment within the furnace. FRT Machinery’s furnaces are equipped with features that facilitate this, such as adjustable vents and insulation to maintain even heat distribution. By carefully monitoring the process, you can ensure that the gold melts smoothly without oxidizing, preserving its quality.

Safety Measures When Smelting Gold

Safety is paramount when working with molten metals. Proper protective gear, including heat-resistant gloves, aprons, and face shields, should always be worn during the smelting process. FRT Machinery emphasizes the importance of adhering to safety guidelines to prevent accidents. Training employees on emergency procedures and having fire suppression systems readily available further enhances workplace safety.

Post-Smelting Refining Techniques

After smelting, refining the gold is often necessary to remove impurities and achieve the desired purity level. FRT Machinery provides solutions for refining processes, including electrolysis and chemical treatments. These methods help in purifying the gold, making it suitable for various applications. Understanding these techniques allows for better control over the final product’s quality, ensuring it meets industry standards.

Tips for Efficient Gold Smelting

To maximize efficiency and minimize waste during the smelting of gold items, consider implementing a few best practices. For instance, preheating the crucible can reduce energy consumption and speed up the melting process. Regular maintenance of your smelting equipment, as recommended by FRT Machinery, ensures optimal performance and longevity. Additionally, keeping detailed records of each smelting batch helps in identifying areas for improvement and maintaining consistency.

By following these guidelines and utilizing the advanced technology provided by FRT Machinery, you can achieve excellence in smelting gold items. Whether for commercial purposes or personal projects, mastering the art of gold smelting opens up endless possibilities in creating beautiful and valuable products.