Smelting Gold Plated Jewelry

Smelting Gold Plated Jewelry: A Comprehensive Guide

Smelting gold plated jewelry involves a meticulous process designed to extract precious metals from items that have seen their best days. Whether you’re a jeweler looking to reclaim gold from outdated pieces or an enthusiast interested in recycling, understanding the nuances of smelting can be incredibly rewarding. This guide will walk you through the essential steps, precautions, and techniques involved in smelting gold plated jewelry.

Preparing for Smelting Gold Plated Jewelry

Before diving into the smelting process, it’s crucial to prepare your workspace and materials properly. Safety should always come first. Wear protective gear such as gloves, goggles, and a respirator mask. Ensure that your work area is well-ventilated and free from flammable materials. Next, gather all necessary tools including a crucible, furnace, tongs, and flux. Flux helps purify the molten metal by removing impurities. Preparing these items ensures a smoother smelting experience.

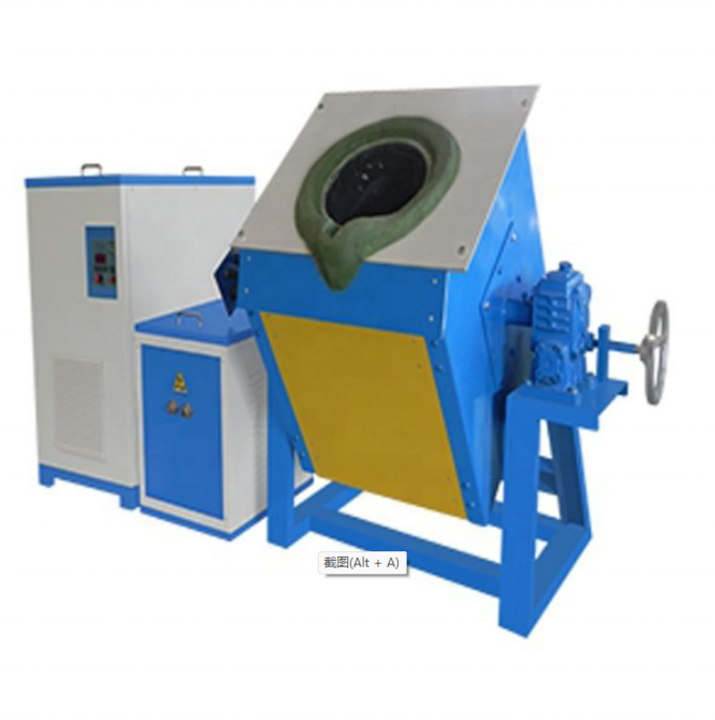

Selecting the Right Equipment for Smelting Gold Plated Jewelry

Choosing the right equipment is key to successfully smelting gold plated jewelry. FRT Machinery offers a range of furnaces specifically designed for this purpose. These furnaces provide precise temperature control, which is vital when dealing with gold and other precious metals. Additionally, consider investing in high-quality crucibles that can withstand the extreme temperatures required for smelting. Proper equipment not only enhances efficiency but also prolongs the lifespan of your tools.

The Process of Smelting Gold Plated Jewelry

The actual smelting process begins with crushing the jewelry into smaller pieces. This increases the surface area exposed to heat, facilitating faster melting. Place the crushed pieces into the crucible and add a small amount of borax or flux. Gradually increase the temperature in your furnace until the gold melts. It’s important to monitor the temperature closely to avoid overheating, which could lead to loss of metal due to vaporization.

Cooling and Casting After Smelting Gold Plated Jewelry

Once the gold has melted, carefully pour it into molds using tongs. Allow the molten metal to cool and solidify. Cooling times vary depending on the size and shape of the mold, but typically take between 15 minutes to an hour. After cooling, remove the cast gold from the mold. You may notice some impurities or slag attached to the metal; these can usually be removed by filing or sanding.

Refining the Gold Post-Smelting

Although smelting removes many impurities, further refining might be necessary for achieving pure gold. Electrolysis is one method used to refine gold, where an electric current passes through a solution containing the metal. This process separates gold from other metals and impurities, resulting in a higher purity level. Alternatively, chemical methods like aqua regia can be employed for purification.

Safety Considerations When Smelting Gold Plated Jewelry

Safety must never be compromised during any step of the smelting process. Always work in a well-ventilated area and wear appropriate protective gear. Be cautious when handling hot crucibles and molten metal. Avoid direct contact with fumes generated during smelting, as they can be harmful if inhaled. Following safety guidelines ensures a safer and more enjoyable smelting experience.

By following these steps and precautions, you can effectively smelt gold plated jewelry, turning old or unwanted pieces into valuable resources. Whether you’re doing this professionally or as a hobby, understanding the process and having the right equipment from FRT Machinery will greatly enhance your results.