Smelting Gold Using Borax

Smelting Gold Using Borax: A Safer, More Efficient Process

The Basics of Borax for Smelting Gold

Gold smelting is a crucial process in the extraction of gold from its ore. Traditionally, this process involved the use of mercury, which poses significant environmental and health risks. However, FRT Machinery has pioneered the use of borax in gold smelting, offering a safer alternative that enhances efficiency while reducing harmful impacts.

Advantages of Using Borax in Gold Smelting

Borax, a naturally occurring mineral, serves as an excellent flux agent in the smelting process. When used correctly, it lowers the melting point of gold, making it easier to separate from impurities. This method not only increases the purity of the extracted gold but also significantly reduces the environmental footprint compared to traditional methods involving mercury.

Equipment Needed for Borax-Based Gold Smelting

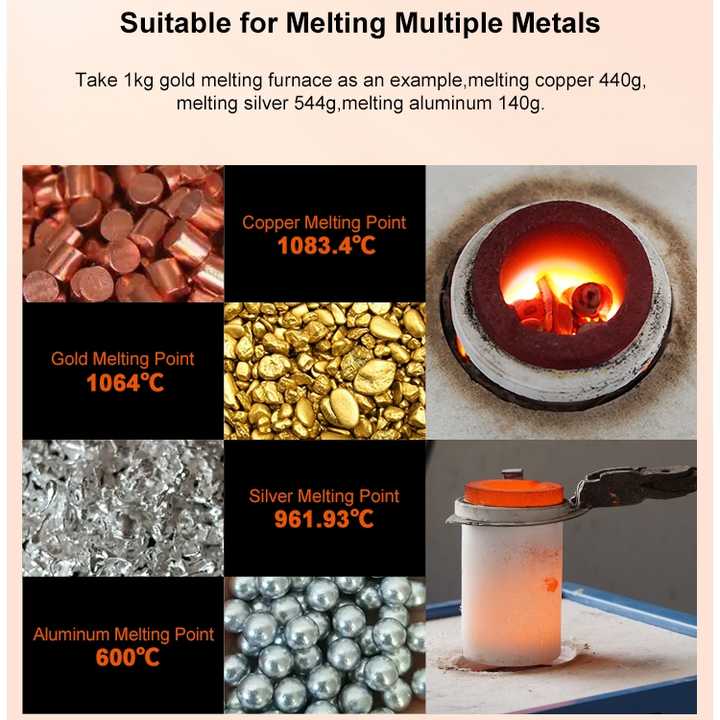

To effectively utilize borax in smelting gold, specific equipment is necessary. FRT Machinery offers a range of high-quality tools designed specifically for this purpose. These include furnaces capable of reaching the required temperatures, crucibles made of materials resistant to extreme heat, and protective gear for operators. By investing in the right equipment, gold smelters can ensure both safety and efficiency.

Step-by-Step Guide to Smelting Gold Using Borax

The process begins by crushing the gold ore into small particles. This step increases the surface area, facilitating better contact between the ore and the borax. Next, mix the crushed ore with borax in a crucible and place it inside the furnace. Heating the mixture to the appropriate temperature causes the gold to melt and separate from other materials, which form a slag on top. Once cooled, the gold can be easily separated from the slag.

Environmental Benefits of Borax in Gold Smelting

One of the most compelling reasons to adopt borax in gold smelting is its environmental impact. Unlike mercury, which can contaminate water sources and harm wildlife, borax is non-toxic and biodegradable. By switching to borax, smelters contribute to cleaner air and water, promoting sustainability within the industry.

Economic Viability of Borax-Based Smelting

Despite initial concerns about cost, the economic benefits of using borax in gold smelting outweigh the costs. The higher purity of gold achieved through this method often leads to better market prices. Additionally, reduced operational costs associated with safety measures and waste management make borax a more economical choice in the long run.

Future Prospects for Borax in Gold Smelting

As awareness grows regarding the advantages of borax over mercury, more and more industries are adopting this eco-friendly method. FRT Machinery continues to innovate, developing new techniques and equipment to further enhance the efficiency and sustainability of gold smelting. The future looks bright for those who choose to embrace this safer, greener approach.

By transitioning to borax-based gold smelting, industries can achieve a balance between productivity and environmental stewardship, setting a new standard for responsible mining practices.