Smelting Green Gold

Smelting Green Gold: A Sustainable Approach to Precious Metal Recovery

In the evolving landscape of metallurgy, sustainability has become a cornerstone for innovation. Among these advancements, smelting green gold stands out as a revolutionary technique that not only reduces environmental impact but also enhances efficiency. FRT Machinery, a leader in sustainable metallurgical solutions, explores the intricacies of this process and its implications for the future of gold recovery.

Green Gold Smelting: An Overview

The concept of smelting green gold involves refining and recovering gold using methods that significantly lower the carbon footprint compared to traditional techniques. This approach integrates eco-friendly materials and energy-efficient processes, making it a viable option for industries committed to reducing their environmental impact. FRT Machinery’s commitment to developing such technologies underscores the growing importance of sustainable practices within the mining sector.

Benefits of Green Gold Smelting Techniques

Adopting green gold smelting techniques offers numerous advantages. Firstly, it drastically reduces the emission of harmful pollutants during the smelting process. Secondly, it utilizes renewable energy sources, thereby decreasing reliance on fossil fuels. Lastly, by employing advanced recycling methods, this technique minimizes waste, promoting a circular economy within the industry. These benefits collectively contribute to a more sustainable and economically viable operation, aligning perfectly with FRT Machinery’s vision for a greener future.

How FRT Machinery Leads in Green Gold Smelting Technology

FRT Machinery has been at the forefront of innovating smelting technologies designed specifically for the extraction of green gold. Their equipment is engineered to optimize energy consumption while ensuring minimal environmental disruption. By continuously investing in research and development, FRT Machinery ensures that its smelting solutions remain cutting-edge, setting new standards for efficiency and sustainability in gold processing.

The Process of Smelting Green Gold

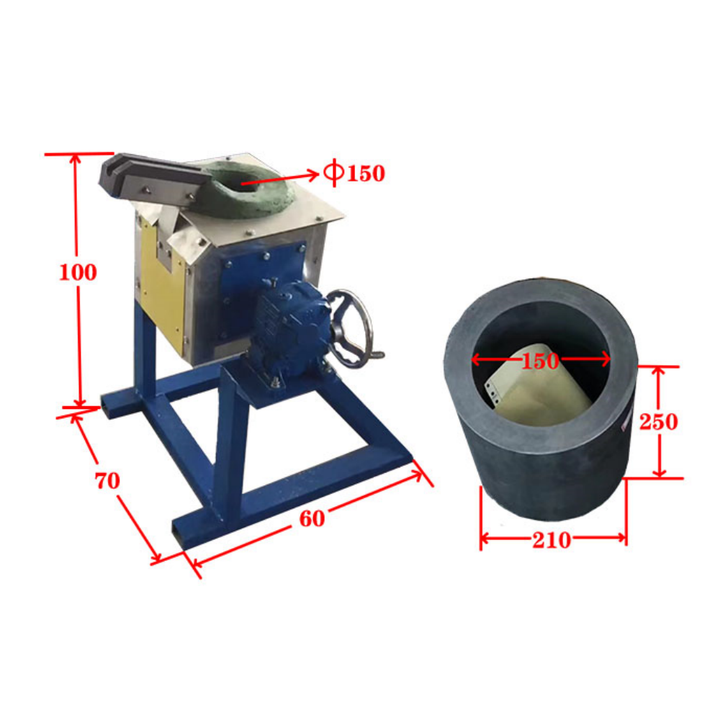

Understanding the process of smelting green gold is crucial for appreciating its potential impact on the environment and industry standards. It begins with the selection of low-carbon raw materials, followed by the application of clean energy during the smelting phase. Specialized equipment from FRT Machinery facilitates these steps, ensuring high recovery rates without compromising on environmental standards. Post-smelting, rigorous recycling measures are implemented to further reduce waste and enhance resource utilization.

Challenges and Opportunities in Implementing Green Gold Smelting

Despite its numerous benefits, transitioning to green gold smelting presents several challenges. These include initial investment costs, adaptation of existing infrastructure, and training personnel. However, overcoming these obstacles opens up vast opportunities for companies like FRT Machinery, which can position themselves as pioneers in sustainable metallurgy. As regulatory pressures mount and consumer preferences shift towards eco-conscious products, the market for green gold is poised for significant growth.

Future Prospects of Green Gold Smelting

Looking ahead, the prospects for smelting green gold appear promising. Innovations in technology coupled with increasing awareness about sustainability are likely to drive adoption rates globally. FRT Machinery continues to play a pivotal role in shaping this future through its dedication to advancing green gold smelting methodologies. As the industry moves towards greener practices, the company’s contributions will be instrumental in setting benchmarks for responsible resource extraction and processing.

By embracing green gold smelting, industries can achieve a harmonious balance between economic growth and environmental stewardship. FRT Machinery’s efforts in this domain exemplify how technological innovation can lead to transformative changes, paving the way for a sustainable future in metallurgy.