Smelting Scrap Silver With Solder

Smelting Scrap Silver With Solder: A Comprehensive Guide

Smelting scrap silver with solder is a process that requires precision and expertise to ensure optimal results. Whether you’re a jeweler looking to reclaim precious metals from old pieces or a hobbyist interested in refining metals, understanding the nuances of smelting scrap silver can be incredibly valuable. In this article, FRT Machinery explores the techniques and equipment necessary for successful smelting, providing insights into how to maximize efficiency and safety.

Understanding the Basics of Smelting Scrap Silver With Solder

Before diving into the specifics of smelting scrap silver with solder, it’s essential to understand the basics. Smelting involves heating metal to its melting point and separating it from impurities. When dealing with scrap silver, solder—often composed of tin and lead—can complicate the process due to its lower melting point. Proper smelting requires specialized equipment and adherence to safety protocols to ensure the removal of solder and purification of silver.

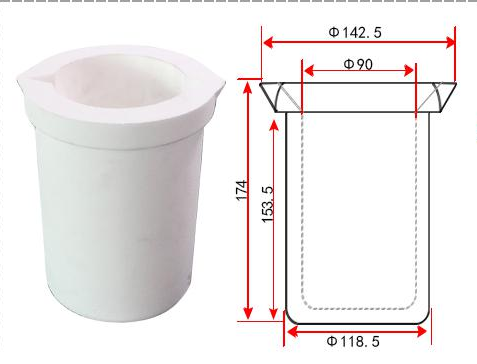

Selecting the Right Equipment for Smelting Scrap Silver With Solder

To effectively smelt scrap silver with solder, one must choose the right tools and machinery. FRT Machinery offers a range of solutions designed specifically for this purpose. Crucibles capable of reaching high temperatures without degrading, along with furnaces that provide even heat distribution, are fundamental. Additionally, protective gear such as gloves and goggles is crucial for safeguarding against burns and other hazards associated with molten metals.

Preparing Materials for Smelting Scrap Silver With Solder

Preparation is key when smelting scrap silver with solder. Before beginning, all materials should be cleaned thoroughly to remove dirt, oils, and other contaminants that could affect the purity of the final product. Breaking down larger pieces of scrap into smaller chunks can also enhance the efficiency of the smelting process by allowing for more uniform heating and melting.

The Smelting Process for Scrap Silver With Solder

The actual smelting process begins by placing prepared scrap silver and solder into a crucible within a furnace. Gradually increasing the temperature allows for controlled melting. It’s important to monitor the temperature closely to prevent overheating, which can lead to the loss of silver through vaporization. Once melted, impurities rise to the surface as slag, which can then be skimmed off, leaving behind pure silver.

Post-Smelting Treatment of Scrap Silver With Solder

After smelting, the silver must be cooled and solidified. Cooling too quickly can result in a brittle, flawed ingot; therefore, controlled cooling is recommended. Once cooled, the ingot should be tested for purity and can then be used for various applications, from jewelry making to industrial uses.

Safety Considerations When Smelting Scrap Silver With Solder

Safety should always be a top priority when working with molten metals. FRT Machinery emphasizes the importance of following strict safety guidelines. This includes using appropriate ventilation to avoid inhaling fumes, ensuring the workspace is free from flammable materials, and employing proper handling techniques to prevent accidents.

By following these steps and utilizing the right equipment, smelting scrap silver with solder can be a rewarding and profitable endeavor. FRT Machinery is dedicated to providing the tools and knowledge necessary for success in this specialized field. Whether you’re just starting out or looking to refine your techniques, remember that patience and precision are key components of effective smelting.