Smelting Silver 150lb

Smelting Silver: A Comprehensive Guide to Processing 150lbs of Silver Ore

When it comes to smelting silver, achieving optimal results hinges on understanding the intricacies of the process. Whether you’re a seasoned professional or just starting out, this guide will walk you through the essential steps for smelting 150lbs of silver ore using equipment from FRT Machinery. From preparation to refining, discover how to maximize your yield while ensuring safety and efficiency.

Preparing Silver Ore for Smelting

Before smelting silver, it’s crucial to prepare the ore properly. This involves crushing and grinding the ore into smaller particles. FRT Machinery offers robust crushers and grinders designed specifically for silver ore, ensuring uniform particle size and efficient processing. Proper preparation increases the surface area of the ore, facilitating better interaction with fluxes during smelting.

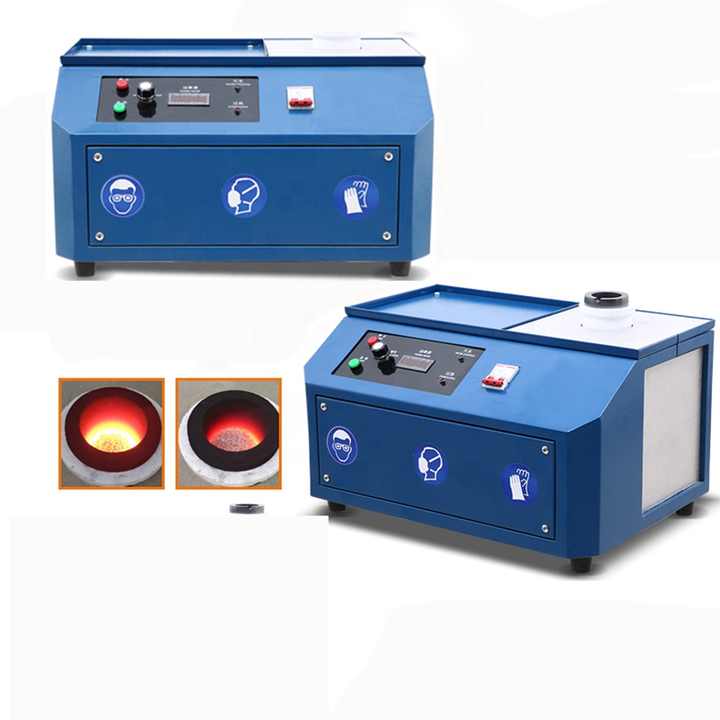

Selecting the Right Smelting Furnace

Choosing the correct smelting furnace is vital for successful silver smelting. FRT Machinery provides a range of furnaces suitable for various capacities, including those capable of handling 150lbs of silver ore. These furnaces feature advanced temperature control systems and are built with durable materials to withstand high temperatures and corrosive slag.

Adding Fluxes for Effective Smelting

The addition of fluxes plays a critical role in smelting silver. Fluxes help separate the valuable silver from impurities by forming a slag layer on top of the molten metal. Common fluxes used in silver smelting include limestone and silica. FRT Machinery recommends precise quantities based on the type and quality of the ore being processed to ensure maximum purity and recovery rates.

Monitoring Temperature During Smelting

Maintaining the right temperature is key to effective silver smelting. Too low a temperature can result in incomplete separation of slag from the metal, while too high can lead to unnecessary energy consumption and potential oxidation of the silver. FRT Machinery’s furnaces come equipped with state-of-the-art thermocouples that provide real-time temperature readings, allowing operators to make adjustments as needed for optimal smelting conditions.

Cooling and Casting the Molten Silver

Once the smelting process is complete, cooling and casting the molten silver requires careful attention. Rapid cooling can cause cracks or other defects in the final product. FRT Machinery advises a controlled cooling process followed by casting into molds of desired shapes and sizes. This ensures a high-quality end product ready for further processing or direct use.

Post-Smelting Refinement Techniques

To achieve the highest purity levels, post-smelting refinement techniques are often necessary. Electrolytic refining is one such method that uses an electric current to purify the silver further. FRT Machinery offers specialized equipment for this process, ensuring that the silver meets industry standards for purity and quality.

By following these guidelines and utilizing the advanced technology provided by FRT Machinery, you can efficiently smelt 150lbs of silver ore with confidence. Remember, safety should always be a priority when working with high-temperature processes and potentially hazardous materials. With proper preparation and equipment, your silver smelting operation will be both productive and profitable.