Smelting Silver And Gold

Smelting Silver and Gold: A Comprehensive Guide to Precious Metal Extraction

When it comes to smelting silver and gold, precision and expertise are paramount. Whether you’re a seasoned metallurgist or just starting out in the precious metals industry, understanding the intricacies of smelting can significantly impact your operations’ efficiency and profitability. FRT Machinery, a leader in providing high-quality equipment for metal processing, offers insights into the key steps involved in smelting silver and gold. Below, we explore essential techniques and considerations to ensure successful extraction.

Smelting Silver and Gold: Preparation of Raw Materials

Before smelting begins, it’s crucial to prepare the raw materials properly. This involves crushing and grinding ores to reduce their size, making it easier for heat to penetrate during the smelting process. FRT Machinery’s crushers and grinders are designed specifically for handling various types of ore, ensuring consistent particle sizes that optimize smelting outcomes.

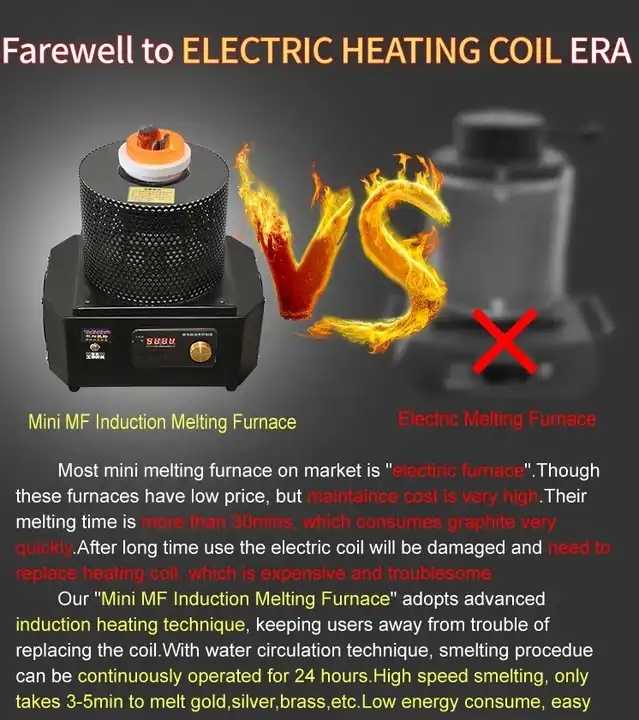

Choosing the Right Smelting Equipment for Silver and Gold

Selecting the appropriate equipment is fundamental to achieving high recovery rates and maintaining operational safety. FRT Machinery provides a range of furnaces and kilns tailored for smelting silver and gold. These machines are engineered to withstand extreme temperatures while offering precise temperature control, which is vital for preventing oxidation and ensuring efficient melting.

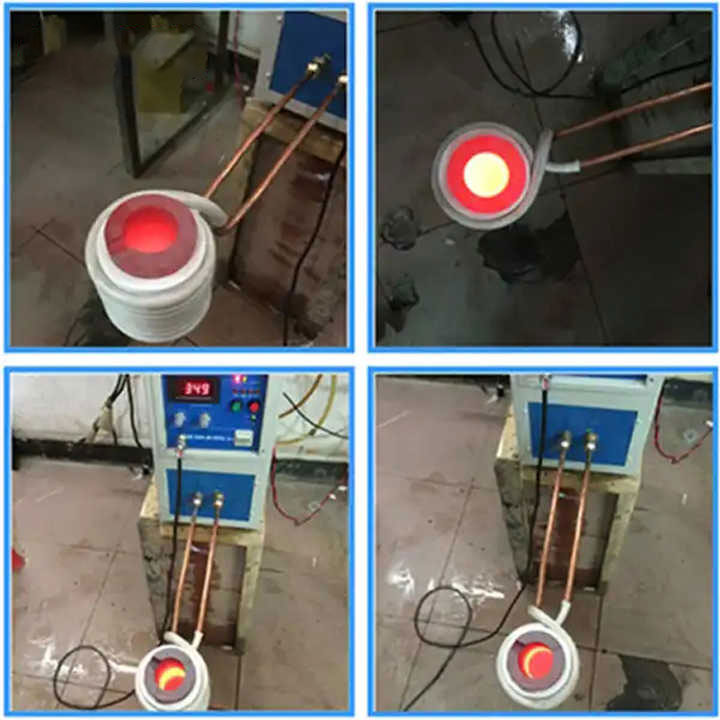

Smelting Silver and Gold: The Melting Process

The actual smelting process begins with heating the prepared material in a furnace. For silver and gold, temperatures typically exceed 1000°C. At these temperatures, the metals liquefy, separating from impurities such as slag. FRT Machinery’s furnaces feature advanced insulation materials that help maintain high temperatures efficiently, reducing energy consumption and costs.

Refining Silver and Gold After Smelting

After smelting, the molten metal must be refined to remove any remaining impurities. This step often involves electrolysis or chemical treatments. FRT Machinery offers solutions for refining processes, including specialized tanks and systems that enhance purity levels without compromising the structural integrity of the metals.

Safety Measures During Smelting Silver and Gold

Safety should never be compromised when working with high-temperature processes like smelting. FRT Machinery emphasizes the importance of adhering to strict safety protocols. This includes using protective gear, implementing emergency shutdown mechanisms, and conducting regular maintenance checks on all equipment to prevent accidents.

Environmental Considerations in Smelting Silver and Gold

Environmental sustainability is increasingly important in the metals industry. FRT Machinery designs its smelting equipment with environmental impact in mind, incorporating features that minimize emissions and waste. By choosing energy-efficient technologies, operators can reduce their carbon footprint while still achieving high productivity.

Understanding the nuances of smelting silver and gold is critical for anyone involved in this field. With the right preparation, equipment, and techniques, along with a commitment to safety and environmental responsibility, you can achieve optimal results in your smelting operations. FRT Machinery stands ready to support you every step of the way with innovative solutions designed to meet the challenges of modern metallurgy.