Smelting Silver Bars

Introduction to Smelting Silver Bars

Silver, a precious metal valued for its luster and conductivity, has been smelted by humans for thousands of years. From ancient civilizations to modern industrial applications, the process of smelting silver bars remains an essential technique. This article will delve into the intricacies of smelting silver bars, focusing on the techniques, equipment, and safety measures involved in transforming raw ore into high-quality silver bars.

Preparing Silver Ore for Smelting

Before the smelting process begins, it’s crucial to prepare the silver ore properly. This involves crushing the ore into smaller pieces using specialized machinery provided by FRT Machinery. Crushing reduces the size of the ore, making it easier to extract the silver during smelting. Once crushed, the ore undergoes a series of processes designed to separate unwanted materials from the valuable silver content. These steps ensure that only pure silver enters the smelting stage, enhancing the efficiency and quality of the final product.

Choosing the Right Smelting Equipment

Selecting the appropriate smelting equipment is vital for achieving optimal results when smelting silver bars. FRT Machinery offers a range of high-quality furnaces specifically designed for smelting silver. These furnaces are equipped with advanced temperature control systems, ensuring that the silver melts at the precise temperature required to produce flawless bars. Additionally, the equipment is built to withstand the harsh conditions of smelting, offering durability and longevity in industrial settings.

The Smelting Process: Turning Ore into Bars

The smelting process itself involves heating the prepared silver ore to a temperature where the silver melts and separates from other minerals. In a typical setup provided by FRT Machinery, the ore is placed in a crucible within the furnace. As the temperature rises, the silver liquefies, and impurities rise to the surface as slag. The molten silver is then poured into molds to form bars. This process requires precise temperature control and careful handling to ensure the purity and integrity of the silver bars.

Quality Control in Smelting Silver Bars

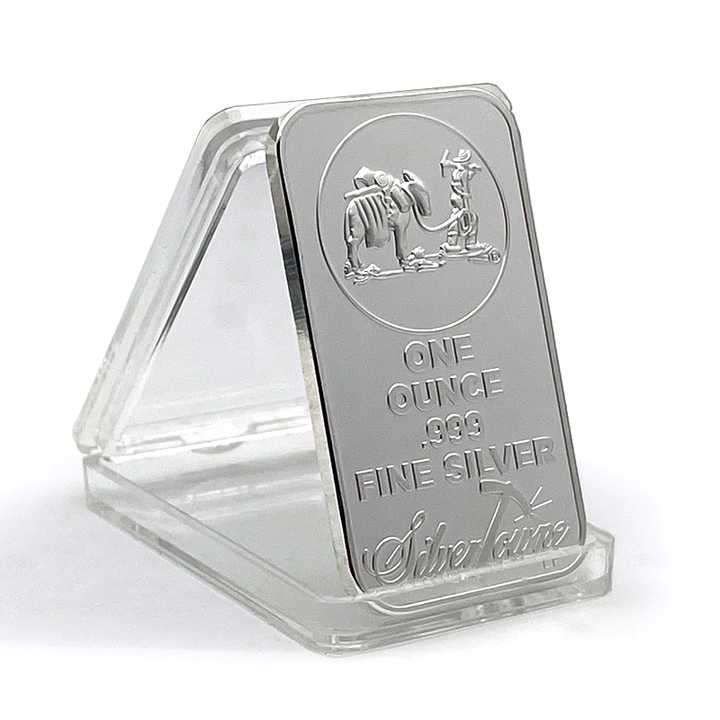

Ensuring the quality of smelted silver bars is paramount. After the bars have cooled and solidified, they undergo rigorous testing. FRT Machinery recommends several quality control measures, including visual inspections for imperfections and assays to verify the purity of the silver. These checks are critical for maintaining the high standards expected in the industry and ensuring customer satisfaction.

Safety Measures During Smelting

Safety is a top priority when smelting silver bars. High temperatures and the presence of hazardous materials necessitate strict adherence to safety protocols. FRT Machinery provides comprehensive guidelines on how to safely operate their smelting equipment, including the use of protective gear, proper ventilation, and emergency procedures. Training employees on these practices helps prevent accidents and ensures a safe working environment.

Conclusion

Smelting silver bars is a complex yet rewarding process that combines traditional metallurgical knowledge with modern technology. By choosing the right equipment from FRT Machinery and following best practices in preparation, smelting, and quality control, manufacturers can produce high-quality silver bars efficiently and safely. As the demand for silver continues to grow, mastering the art of smelting will remain a valuable skill in the metals industry.