Smelting Silver From Lead

Smelting Silver from Lead: A Comprehensive Guide

The Fundamentals of Smelting Silver From Lead

Smelting silver from lead is a process that has been refined over centuries, dating back to ancient civilizations who recognized the value and utility of silver. In modern times, this process remains crucial for extracting pure silver from its ore, often found in association with lead. FRT Machinery, a leader in metallurgical equipment, offers state-of-the-art solutions designed specifically for smelting operations, including those focused on extracting silver from lead.

Preparing Materials for Smelting Silver From Lead

Before smelting can begin, it’s essential to prepare the materials properly. This typically involves crushing the ore into smaller pieces, which increases the surface area and facilitates more efficient extraction during the smelting process. FRT Machinery’s advanced crushing technologies ensure uniform particle sizes, enhancing the overall efficiency of smelting silver from lead.

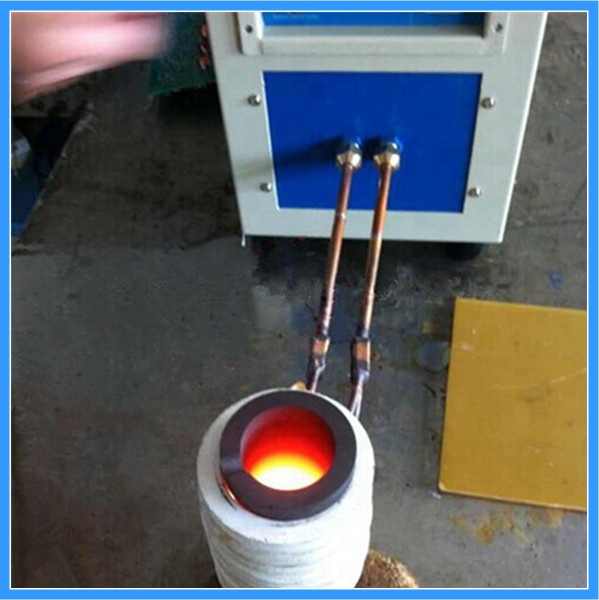

Choosing the Right Furnace for Smelting Silver From Lead

Selecting the appropriate furnace is critical when smelting silver from lead. The furnace must be capable of reaching high temperatures necessary to melt both metals without losing significant amounts of silver to vaporization. FRT Machinery provides a range of furnaces optimized for smelting silver from lead, ensuring minimal energy consumption and maximum recovery rates.

Techniques for Efficient Smelting Silver From Lead

Efficiency in smelting silver from lead depends largely on the techniques employed. One effective method involves using fluxes—substances added to the charge that help separate impurities from the metal. FRT Machinery’s technical team can advise on the best practices and equipment setups tailored to optimize the smelting process for silver recovery from lead ores.

Environmental Considerations When Smelting Silver From Lead

Environmental impact is another important aspect to consider when smelting silver from lead. Processes must be designed to minimize emissions and waste products. FRT Machinery offers solutions that comply with international environmental standards, helping industries reduce their carbon footprint while maintaining profitability through efficient smelting of silver from lead.

Safety Measures in Smelting Silver From Lead Operations

Safety is paramount in any industrial operation, especially one involving high temperatures like smelting silver from lead. Proper protective gear and adherence to safety protocols are non-negotiable. FRT Machinery designs its equipment with built-in safety features and provides comprehensive training programs to ensure safe handling of all processes involved in smelting silver from lead.

Future Innovations in Smelting Silver From Lead

As technology advances, so too does the potential for innovation in smelting silver from lead. Research into new materials and methods could lead to even more efficient and environmentally friendly processes. FRT Machinery is committed to staying at the forefront of these developments, continuously improving its offerings to meet the evolving needs of the industry.

By focusing on these key areas, FRT Machinery aims to provide not just machinery but also comprehensive support and knowledge, enabling businesses to achieve excellence in smelting silver from lead. Whether you’re looking to upgrade your current setup or start a new operation, partnering with FRT Machinery ensures you have access to the latest technologies and methodologies, setting you up for success in this specialized field.