smelting silver ore

Smelting Silver Ore A Comprehensive Guide

Smelting silver ore is a process used to extract silver from its raw form by separating it from the surrounding minerals and impurities. The process of smelting silver ore has been used for centuries and remains a critical step in refining the metal for various industrial, commercial, and investment purposes. This guide will explore the essentials of smelting silver ore, the tools required, and the steps involved in the process.

Understanding Silver Ore

Silver ore is a naturally occurring mineral that contains silver combined with other elements such as sulfur, copper, or lead. In its raw form, silver is not typically found in its pure state, and the metal must be separated from these other elements through smelting.

Silver ores are often found in combination with other precious metals, such as gold, as well as base metals like copper and zinc. The presence of these other elements can complicate the smelting process, as each metal has a different melting point and behaves differently when subjected to heat.

Common Types of Silver Ore

Several types of silver ore exist, each requiring a slightly different approach to smelting. The most common types include:

- Argentite: A silver sulfide ore that is one of the primary sources of silver.

- Galena: Often a lead ore that contains significant amounts of silver.

- Chlorargyrite: A silver chloride mineral that is less common but valuable for silver extraction.

Tools and Equipment for Smelting Silver Ore

Smelting silver ore requires specialized tools and equipment designed to withstand high temperatures and handle molten metal. The following items are essential for the process:

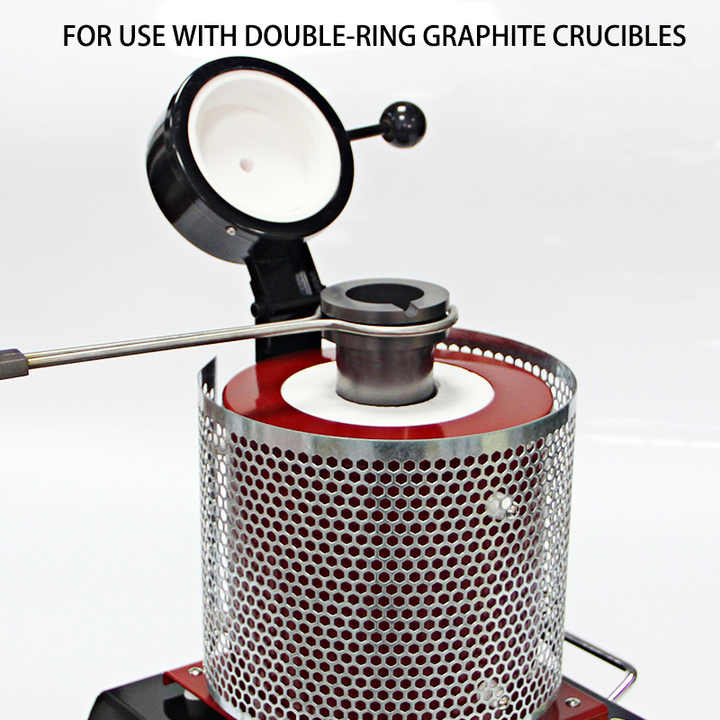

1. Furnace

A furnace capable of reaching temperatures above 1,763°F (961.8°C), the melting point of silver, is required. Small, propane-powered furnaces are available for hobbyists, while industrial-scale operations may use large electric or natural gas furnaces.

2. Crucible

A crucible is a heat-resistant container used to hold the silver ore as it melts. Crucibles are typically made from materials like graphite, which can withstand the extreme heat needed to smelt silver.

3. Flux

Flux is a chemical compound added to the smelting process to help remove impurities from the molten metal. Borax is a common flux used in silver smelting because it helps lower the melting point and assists in separating the metal from non-metallic waste materials.

4. Molds

Molds are used to shape the molten silver once it has been separated from the impurities. These molds can be simple ingot molds or more complex designs, depending on the desired final product.

5. Safety Gear

Smelting silver ore involves working with very high temperatures and potentially hazardous materials, so proper safety equipment is crucial. This includes heat-resistant gloves, goggles, and protective clothing to prevent burns and injuries.

Steps Involved in Smelting Silver Ore

1. Preparing the Ore

Before the smelting process begins, the silver ore must be thoroughly cleaned and crushed into smaller pieces. This ensures that the furnace heats the ore evenly and helps separate the silver from other materials.

2. Heating the Furnace

The furnace is then preheated to the necessary temperature for melting silver, which is typically between 1,800°F and 2,000°F (982°C to 1,093°C). The crucible is placed inside the furnace, and the ore is added.

3. Adding Flux

As the ore begins to melt, flux is added to the crucible. The flux helps remove impurities by binding with them and forming slag, a waste material that floats on top of the molten silver. This slag is skimmed off, leaving behind purer silver.

4. Separating the Silver

Once the slag is removed, the molten silver is poured into molds to cool and solidify. At this stage, the silver is still not entirely pure and may require further refining to achieve the desired purity level.

5. Refining the Silver

Additional refining processes may be required to purify the silver further. This can include techniques such as electrolysis or chemical refining, depending on the desired final purity of the metal.

Benefits of Smelting Silver Ore

Smelting silver ore offers several benefits, particularly for those in the precious metals industry. By extracting silver from its natural state, individuals and businesses can obtain valuable silver for use in various applications.

1. Increased Value

Raw silver ore is often worth less than the refined metal due to the presence of impurities and other metals. Smelting allows for the separation of these unwanted materials, resulting in silver that is worth more on the market.

2. Recycling and Sustainability

Smelting is a valuable tool for recycling precious metals. By smelting silver ore, individuals and companies can reclaim valuable silver that would otherwise go to waste. This contributes to environmental sustainability by reducing the need for mining new silver.

3. Purity Control

By controlling the smelting process, individuals can ensure that the silver produced meets their desired purity standards. This is especially important for industries such as jewelry making or electronics, where silver purity is critical.

Challenges of Smelting Silver Ore

Despite its advantages, smelting silver ore also presents some challenges. The process requires significant energy to reach the necessary temperatures, and specialized equipment is needed to handle the high heat and molten metal. Additionally, there are environmental concerns related to the release of harmful gases and the disposal of slag.

Smelting silver ore is also a delicate process that requires careful attention to detail. Failure to properly manage the temperature or add the correct amount of flux can result in poor-quality silver or the loss of valuable metal.

Smelting silver ore is an essential process for extracting silver from its raw form and transforming it into a more valuable and usable metal. With the right tools and knowledge, smelting can be a rewarding practice for both small-scale hobbyists and large industrial operations. By understanding the different types of silver ore, the necessary equipment, and the steps involved, individuals can successfully smelt silver ore and produce high-quality silver for various applications.