Smelting Silver With Borax

Smelting Silver With Borax: A Comprehensive Guide

Smelting silver with borax is an ancient technique that has been refined over centuries. This method allows for the purification of silver ore, separating it from impurities and base metals. Today, FRT Machinery explores this process in detail, highlighting its importance in modern applications.

Borax-Assisted Silver Smelting: An Overview

Borax-assisted silver smelting is a method that utilizes borax to separate silver from other materials. Borax, also known as sodium borate, plays a crucial role in lowering the melting point of impurities, making them easier to remove. This technique is favored by artisans and small-scale miners for its simplicity and effectiveness.

Preparing Materials for Smelting Silver With Borax

Before beginning the smelting process, it’s essential to prepare your materials properly. Silver ore must be crushed into small pieces to increase the surface area exposed to heat. Borax should be powdered finely to ensure it mixes well with the ore. Proper preparation ensures that the smelting process goes smoothly, maximizing the yield of pure silver.

Setting Up the Smelting Equipment

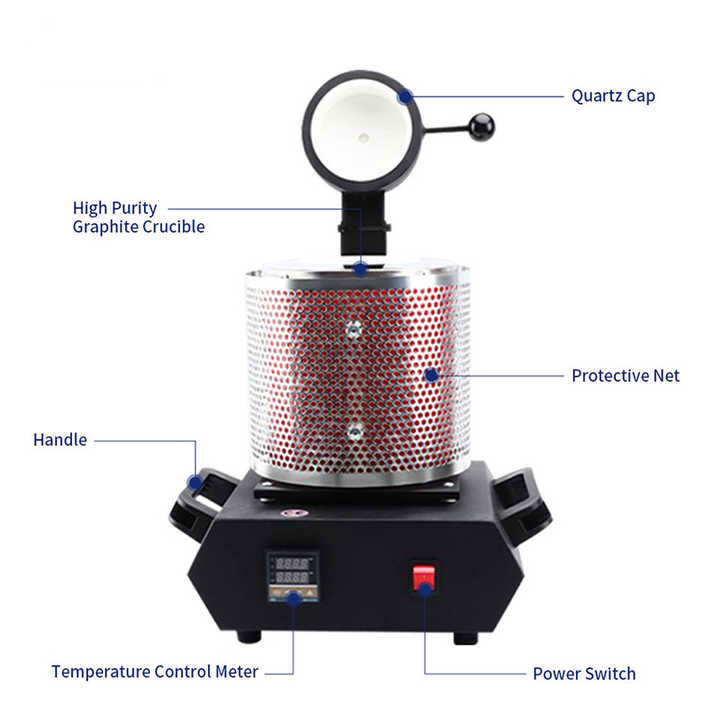

To smelt silver using borax, you’ll need specific equipment. This includes a crucible, furnace, and protective gear such as gloves and goggles. FRT Machinery recommends using high-quality materials for all components to ensure safety and efficiency. The crucible, where the smelting occurs, should be made of a material that can withstand extremely high temperatures without degrading.

The Process of Smelting Silver With Borax

The actual process of smelting begins by heating the crucible in the furnace. Once the temperature reaches around 1100°C, the silver ore and borax mixture is added. The borax melts and forms a slag layer on top of the molten metal, trapping impurities. As the smelting continues, the pure silver sinks to the bottom of the crucible, separated from contaminants.

Cooling and Extracting Pure Silver

After smelting, the next step is cooling and extracting the silver. The crucible is removed from the furnace and allowed to cool gradually. Once cooled, the slag can be broken away, revealing the purified silver underneath. It’s important to handle the crucible carefully during this stage to avoid damaging the precious metal.

Safety Considerations When Smelting Silver With Borax

Safety is paramount when working with high temperatures and chemicals like borax. Always wear appropriate protective gear and work in a well-ventilated area. Ensure that all equipment is in good condition and follow established safety protocols. FRT Machinery emphasizes the importance of training and experience in safely conducting these processes.

By following these steps and precautions, smelting silver with borax can be both productive and safe. Whether you’re a hobbyist looking to refine your skills or a professional seeking efficient methods, understanding the nuances of this technique will undoubtedly benefit your endeavors.