Smelting Silver With Solder

Smelting Silver With Solder: Techniques and Tips for Precious Metal Extraction

Understanding the Basics of Silver Smelting With Solder

Smelting silver with solder is a specialized technique used to extract pure silver from its ore or scrap materials. This process involves heating the silver-containing material to a temperature where the solder melts, allowing the silver to separate from impurities. FRT Machinery, a leading manufacturer in the field, offers equipment designed specifically for this purpose, ensuring a high yield of pure silver.

Choosing the Right Solder for Smelting Silver

Selecting the appropriate solder is crucial when smelting silver. The type of solder used can significantly affect the efficiency and purity of the final product. For optimal results, FRT Machinery recommends using a solder with a low melting point and high thermal conductivity, which facilitates the separation of silver from other elements present in the mixture.

Preparation Steps Before Smelting Silver With Solder

Before beginning the smelting process, it’s essential to prepare both the silver material and the solder properly. This includes cleaning the silver pieces thoroughly to remove any contaminants that could interfere with the smelting process. Additionally, preheating the materials helps ensure uniform melting and enhances the overall effectiveness of the smelting procedure.

Equipment Needed for Efficient Silver Smelting With Solder

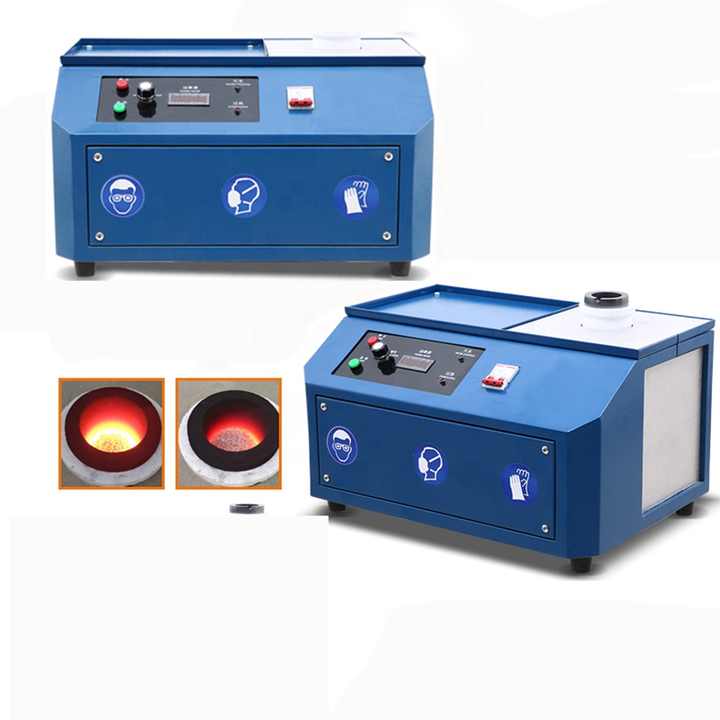

To achieve successful smelting of silver using solder, one must have access to specialized equipment. FRT Machinery provides a range of tools and machinery designed to meet these needs, including furnaces capable of reaching the necessary temperatures and safety gear to protect operators during the process. These tools are engineered to make the smelting experience safe and efficient.

Techniques for Smelting Silver Using Solder

The actual smelting process involves carefully combining the silver and solder within a crucible, then heating them to a high temperature until the solder melts and binds with the silver. Proper control over the heat source is vital to prevent oxidation and loss of silver. FRT Machinery’s advanced furnaces offer precise temperature regulation, making it easier to manage the smelting process effectively.

Post-Smelting Procedures for Processing Smelted Silver

After the smelting process is complete, the resulting silver-solder alloy must be cooled and refined to remove any remaining impurities. FRT Machinery offers cooling systems and refining tools that streamline this phase, ensuring that the silver produced is of the highest quality possible. Following these steps diligently leads to a purer end product, ready for further manufacturing or sale.

Safety Considerations When Smelting Silver With Solder

Safety is paramount when working with high temperatures and potentially hazardous materials like molten metals and solders. FRT Machinery emphasizes the importance of wearing protective gear such as gloves, goggles, and aprons, as well as operating all machinery according to the manufacturer’s guidelines. By prioritizing safety, individuals can minimize risks while maximizing productivity during the smelting process.