smelting sterling silver

Smelting Sterling Silver A Comprehensive Guide

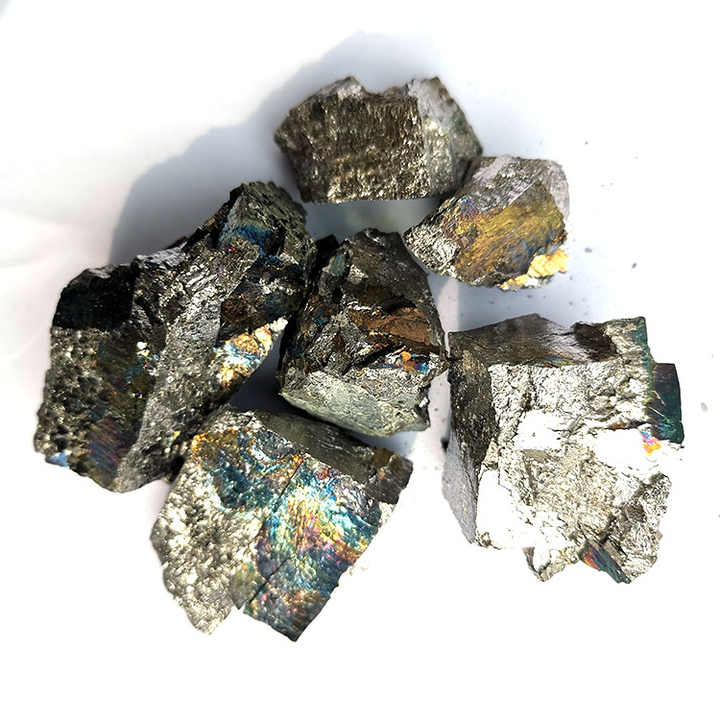

Smelting sterling silver is a process that involves melting down silver to remove impurities and create new silver objects or ingots. Sterling silver, commonly used in jewelry, tableware, and coins, consists of 92.5% pure silver and 7.5% other metals, often copper. This composition makes it durable yet still visually appealing. Smelting sterling silver requires specific tools, materials, and knowledge of the smelting process to achieve optimal results. This article explores the steps involved, the tools needed, and the benefits of smelting sterling silver.

Understanding Sterling Silver

Sterling silver differs from pure silver because of its added alloy, typically copper, which improves its strength and durability. Pure silver is relatively soft and malleable, making it unsuitable for everyday items. Sterling silver retains the aesthetic beauty of silver while being more practical for creating durable products.

Common Uses of Sterling Silver

- Jewelry: Sterling silver is a popular material for making rings, necklaces, bracelets, and earrings.

- Tableware: Silverware, serving trays, and decorative table pieces are often crafted from sterling silver.

- Coins: Some coins, especially collectible or commemorative ones, are made from sterling silver.

Tools and Materials Needed for Smelting Sterling Silver

Before beginning the smelting process, it’s essential to have the proper equipment and materials. These tools ensure the process is safe and effective.

1. Furnace

A high-temperature furnace capable of reaching at least 1,763°F (961.8°C), which is the melting point of silver, is required. Propane or electric furnaces are commonly used for small-scale smelting, while larger operations may use induction furnaces.

2. Crucible

A crucible is a heat-resistant container used to melt the sterling silver. Crucibles made of graphite or ceramic are ideal because they can withstand the intense heat without contaminating the metal.

3. Tongs

Tongs are essential for handling the crucible, especially when removing it from the furnace. Heat-resistant tongs allow for the safe movement of the molten silver.

4. Flux

Flux is a chemical substance added during the smelting process to help separate impurities from the molten metal. Borax is a commonly used flux for silver smelting, as it binds with the impurities and allows them to float to the surface as slag.

5. Molds

Once the silver is melted and impurities are removed, the molten metal is poured into molds to cool and solidify. These molds can shape the silver into ingots, coins, or other forms as needed.

6. Protective Gear

Safety is crucial during the smelting process. Heat-resistant gloves, goggles, and protective clothing help protect the smelter from burns and injuries due to exposure to high heat and molten metal.

Steps Involved in Smelting Sterling Silver

1. Preparing the Sterling Silver

The first step in smelting sterling silver is to prepare the material. Old or damaged sterling silver items, such as broken jewelry or tarnished silverware, can be used as the source material. Ensure the silver is clean and free of dirt or other debris, as this can affect the smelting process.

2. Melting the Silver

The prepared sterling silver is placed in a crucible, which is then inserted into the preheated furnace. The furnace must reach a temperature high enough to melt the silver, which is around 1,763°F (961.8°C). Once the silver begins to melt, it will transition from a solid to a liquid state, allowing impurities to rise to the surface.

3. Adding Flux

Once the sterling silver has melted, flux is added to the crucible. The flux helps to bind with any impurities, creating a layer of slag that floats on top of the molten silver. This slag is then skimmed off, leaving behind purified sterling silver.

4. Pouring the Molten Silver

After removing the impurities, the molten silver is poured into molds. These molds give the silver its desired shape, whether as ingots, coins, or other forms. The silver is left to cool and solidify in the molds.

5. Refining (Optional)

For higher purity, sterling silver may undergo further refining after the initial smelting process. Electrolytic refining is one option, where the silver is purified to remove trace elements of other metals. However, for most sterling silver applications, the initial smelting process is sufficient.

Benefits of Smelting Sterling Silver

Smelting sterling silver offers several advantages, both for individual hobbyists and commercial operations.

1. Recycling and Reusing Silver

Smelting allows for the recycling of old or damaged sterling silver items. Instead of discarding unwanted silverware or jewelry, the smelting process can transform these objects into new, usable items.

2. Creating Custom Silver Products

Smelting provides the opportunity to create custom items from sterling silver. Whether for jewelry making or crafting, molten silver can be poured into molds of various shapes and sizes, allowing for personalized designs.

3. Improving Silver Purity

While sterling silver is already a high-quality material, the smelting process can help remove impurities that may have accumulated over time. This results in cleaner, higher-quality silver.

4. Preserving Value

Smelting sterling silver is an excellent way to preserve the metal’s value. By converting old or scrap silver into new forms, individuals and businesses can retain the intrinsic worth of the silver.

Challenges of Smelting Sterling Silver

While smelting sterling silver offers many benefits, it also comes with challenges that must be addressed.

1. High Temperatures

The process requires extremely high temperatures, which can be dangerous if proper precautions are not taken. Working with molten metal demands careful attention and the right equipment to ensure safety.

2. Dealing with Impurities

Although flux helps remove impurities, some impurities can be stubborn and difficult to eliminate completely. This is especially true for silver that has been used for long periods or exposed to harsh environments.

3. Environmental Concerns

Smelting processes, especially on an industrial scale, can have environmental impacts due to the release of harmful gases and the need for significant energy consumption. Small-scale smelting reduces these risks but still requires responsible handling of materials and waste.

Smelting sterling silver is a valuable process that allows individuals and businesses to recycle, purify, and reshape silver into new, functional forms. With the proper tools and equipment, smelting sterling silver can be done safely and effectively. Whether for creating jewelry, crafting custom items, or preserving the value of silver, smelting is a practical and rewarding endeavor. By following the correct steps and using the right materials, anyone can successfully smelt sterling silver and enjoy the benefits of this ancient metalworking technique.