Smelting Sulfide Gold Concentrate

Smelting Sulfide Gold Concentrate: Enhancing Efficiency and Sustainability

Understanding the Fundamentals of Smelting Sulfide Gold Concentrate

Gold mining operations often encounter sulfide-rich ores, which present unique challenges when it comes to extracting the precious metal. Smelting sulfide gold concentrate is a process that requires specialized knowledge and equipment to ensure both efficiency and environmental compliance. FRT Machinery, a leading provider of advanced smelting solutions, offers innovative technologies designed specifically for processing sulfide concentrates.

Preparation of Sulfide Gold Concentrate Before Smelting

Before smelting sulfide gold concentrate, it is crucial to prepare the material appropriately. This preparation involves several steps including crushing, grinding, and concentrating the ore to remove impurities. FRT Machinery’s state-of-the-art grinding mills and concentrators play a pivotal role in this phase, ensuring that the concentrate is ready for smelting by reducing particle size and increasing gold content.

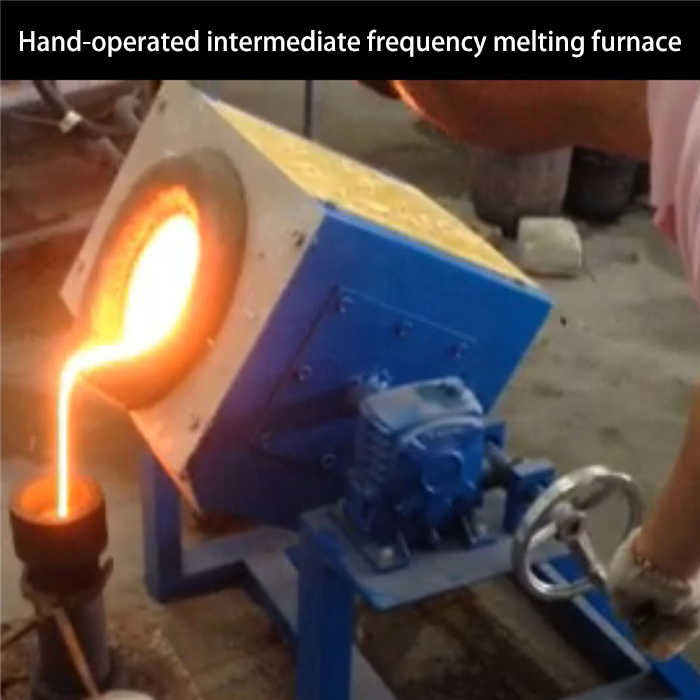

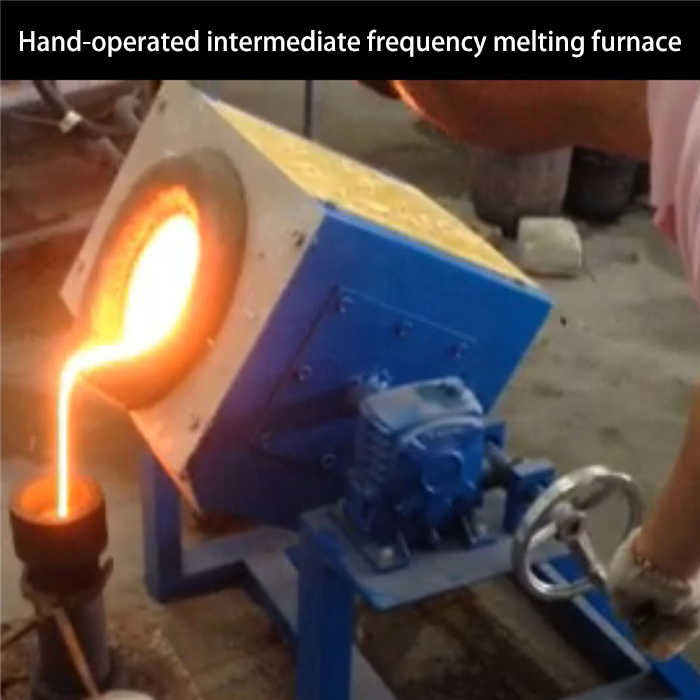

The Role of FRT Machinery in Smelting Sulfide Gold Concentrate

FRT Machinery has developed a comprehensive suite of equipment tailored for smelting sulfide gold concentrates. Their furnaces are engineered to withstand the high temperatures required to melt sulfides and extract gold efficiently. Additionally, these systems incorporate advanced emission control technologies to minimize sulfur dioxide emissions, a critical consideration given the environmental impact of smelting sulfide ores.

Techniques for Efficient Smelting of Sulfide Gold Concentrate

Efficient smelting of sulfide gold concentrate relies on precise temperature control and the use of appropriate fluxes. FRT Machinery’s furnaces are equipped with sophisticated thermal management systems that maintain optimal conditions throughout the smelting process. By using the right combination of flux materials, such as lime or silica, operators can further enhance the separation of gold from sulfide compounds, resulting in higher yields and purer bullion.

Environmental Considerations in Smelting Sulfide Gold Concentrate

Given the environmental concerns associated with smelting sulfide ores, FRT Machinery emphasizes sustainable practices in all its operations. Their systems feature advanced air pollution control devices that capture and neutralize harmful gases, ensuring compliance with stringent environmental regulations. Furthermore, FRT Machinery continuously invests in research to develop more eco-friendly smelting techniques that reduce the industry’s carbon footprint.

Future Innovations in Smelting Sulfide Gold Concentrate

As the global focus shifts towards greener mining practices, FRT Machinery remains committed to pioneering new methods for smelting sulfide gold concentrate. By integrating artificial intelligence and machine learning into their equipment design, they aim to achieve unprecedented levels of efficiency and sustainability. These innovations promise not only to improve the economic viability of gold mining but also to set new standards for environmental responsibility within the sector.

In conclusion, smelting sulfide gold concentrate is a complex process that demands specialized equipment and expertise. With FRT Machinery’s advanced technologies and commitment to sustainability, mining companies can look forward to a future where efficient extraction of gold goes hand-in-hand with responsible stewardship of our planet’s resources.