south east refining inc silver

South East Refining Inc Silver Refining and Services

South East Refining Inc has earned a reputation as one of the prominent silver refining companies in the United States. Known for its efficient processes and customer-focused services, the company handles a wide range of precious metal refining, including silver. This article will explore South East Refining Inc’s silver refining services, its role in the industry, and how it meets the needs of customers looking for high-quality silver refining.

Overview of South East Refining Inc

South East Refining Inc was established with a focus on providing precious metal refining services to industries, jewelers, and individual customers. While the company handles various metals, its silver refining services stand out as a key aspect of its operations. With years of experience in the industry, South East Refining has developed a comprehensive refining system that ensures high purity and customer satisfaction.

The Importance of Silver Refining

Silver is a valuable metal that is used in numerous applications, from jewelry and coins to industrial and technological products. Silver refining involves the process of purifying silver by removing impurities or other metals that may have been mixed during its initial production. This process ensures that the final product meets industry standards for purity, making it suitable for various uses.

Silver is often recovered from scrap materials such as jewelry, electronics, or industrial byproducts, and refining helps in reclaiming the metal in its purest form. South East Refining Inc specializes in these processes, offering a reliable way for businesses and individuals to refine silver and maximize its value.

Silver Refining Process at South East Refining Inc

South East Refining Inc utilizes advanced techniques and equipment for refining silver. The company employs several methods depending on the source of the silver and the purity level required. Here are some common steps involved in their silver refining process:

- Assessment of Silver Scrap: The first step in the refining process is evaluating the silver scrap or materials provided by the customer. South East Refining Inc uses modern testing methods to determine the content and purity of the silver.

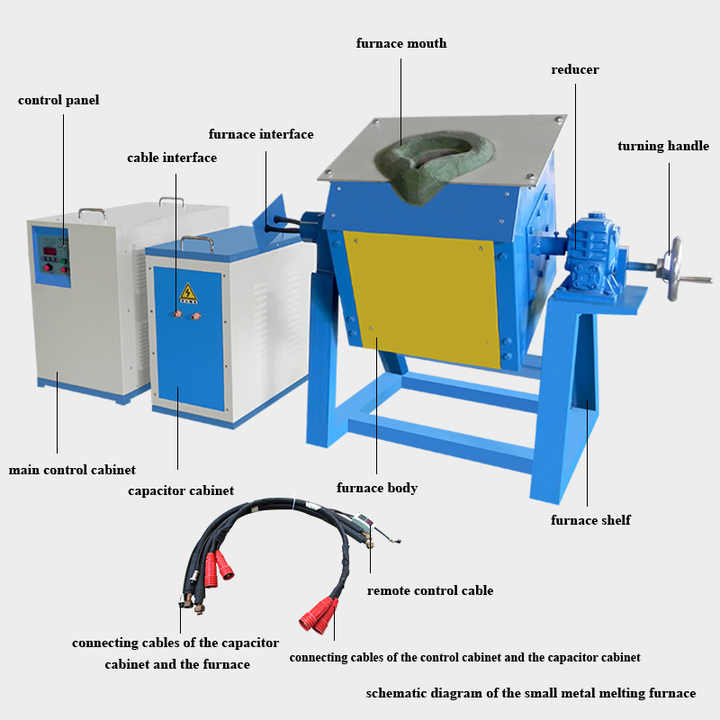

- Melting and Separation: Once the material is assessed, it is melted at high temperatures. During this process, impurities such as base metals are separated from the pure silver. The melting point of silver is 961.8°C (1763°F), and the company’s furnaces are calibrated to ensure efficient separation.

- Refining Techniques: Depending on the material’s composition, South East Refining may use electrolytic refining, chemical methods, or cupellation to further purify the silver. These techniques help remove any remaining impurities, leaving silver with a high purity level, typically above 99.9%.

- Final Product: After refining, the silver is cast into bars, grains, or other forms, depending on the customer’s needs. These refined silver products are then delivered to clients, ready for use in industries such as jewelry manufacturing or investment.

Why Choose South East Refining Inc for Silver Refining?

South East Refining Inc has built a strong reputation for its commitment to quality, efficiency, and customer service. Here are some reasons why businesses and individuals choose South East Refining for their silver refining needs:

- High Purity Silver: The company ensures that its refined silver meets the highest industry standards for purity, making it ideal for a wide range of applications.

- Advanced Refining Techniques: With a focus on using the latest technology and methods, South East Refining can handle various forms of silver scrap, ensuring the best possible refining outcomes.

- Customer-Centric Approach: South East Refining Inc prioritizes customer satisfaction, offering personalized services tailored to meet the needs of each client. Whether refining small amounts of scrap silver or large industrial batches, the company ensures timely processing and transparent communication.

- Competitive Pricing: South East Refining Inc offers competitive pricing for its refining services, helping customers maximize the value of their silver. This, combined with the high-quality final product, makes it a cost-effective solution for silver refining.

Silver Refining for Various Industries

South East Refining Inc serves a variety of industries that require refined silver. Some of the main sectors include:

- Jewelry and Watchmaking: Refined silver is essential for creating high-quality jewelry and watches. South East Refining provides jewelers with pure silver that can be used to craft intricate designs or manufacture luxury pieces.

- Electronics: Silver’s excellent conductivity makes it valuable in electronics manufacturing. The company supplies refined silver for components used in mobile devices, computers, and other electronic equipment.

- Industrial Applications: Refined silver is also used in various industrial processes, such as solar panel production, chemical reactions, and brazing. South East Refining Inc offers silver that meets the purity requirements for these applications.

South East Refining Inc is a trusted name in the silver refining industry, providing high-quality refining services to meet the needs of a wide range of clients. With a focus on purity, efficiency, and customer satisfaction, the company continues to be a reliable partner for those looking to refine silver. Whether you are a jeweler, an electronics manufacturer, or an individual with silver scrap, South East Refining Inc offers the expertise and services necessary to reclaim silver in its purest form.