Steps To Refining Silver

Steps to Refining Silver: A Comprehensive Guide

Silver refining is a meticulous process aimed at purifying raw silver ore into a form suitable for commercial and industrial applications. This guide will walk you through the essential steps involved in refining silver, highlighting techniques used by industry leaders like FRT Machinery. Whether you’re a seasoned metallurgist or new to the field, understanding these processes can help optimize your operations and ensure high-quality results.

Silver Refining: Crushing and Grinding

The first step in refining silver involves reducing the size of the ore to access the embedded silver particles.FRT Machineryoffers robust crushers and grinders designed specifically for this purpose. These machines efficiently break down large chunks of ore into smaller particles, making it easier to extract the valuable silver content. After crushing, the ore undergoes grinding, further reducing its size until it resembles a fine powder. This process increases the surface area of the ore, facilitating more effective extraction of silver during subsequent stages.

Leaching Process in Silver Refining

Once the ore is ground into a fine powder, the next critical step is leaching. This process uses chemicals, typically cyanide solutions, to dissolve the silver from the ore.FRT Machineryprovides advanced leaching tanks equipped with agitators to ensure uniform mixing and maximum contact between the ore and the leaching solution. As the silver dissolves, it forms a soluble complex that can be separated from other minerals. Proper leaching is crucial for maximizing recovery rates and ensuring that minimal silver remains in the residue.

Electrowinning Techniques for Silver Refining

After leaching, the silver-rich solution is directed to electrowinning cells. Here, an electric current is applied to precipitate the dissolved silver onto cathodes.FRT Machinerydesigns and manufactures electrowinning systems that are efficient and easy to maintain. Electrowinning is particularly effective because it allows for the recovery of silver with high purity levels, typically above 99%. Regular monitoring and maintenance of these cells are essential to maintaining optimal performance and preventing contamination.

Purification Methods in Silver Refining

To achieve the highest grades of silver, purification steps are necessary post-electrowinning. This stage involves removing any remaining impurities that could affect the quality of the final product.FRT Machineryrecommends several methods, including electrolytic refining and chemical precipitation, depending on the specific requirements of your operation. Electrolytic refining involves a second round of electrowinning under controlled conditions, while chemical precipitation uses reagents to selectively remove contaminants. Both methods contribute significantly to enhancing the purity of the silver.

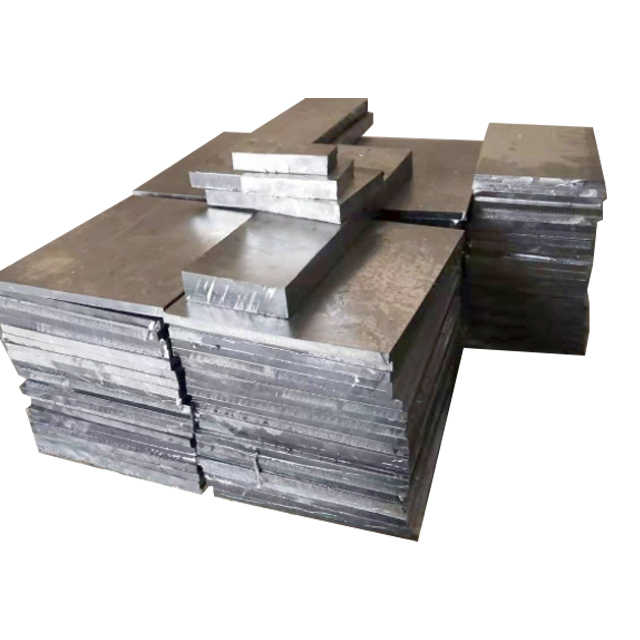

Final Processing of Refined Silver

The final processing stage prepares the refined silver for market. This includes melting the silver and casting it into bars or ingots.FRT Machineryprovides state-of-the-art melting furnaces that operate at high temperatures to ensure complete melting of the silver. Once melted, the silver is poured into molds where it cools and solidifies into the desired shape. Quality checks are performed at this stage to confirm that the silver meets the required purity standards.

Sustainability in Silver Refining Processes

As environmental concerns become increasingly important, many companies are looking for ways to make their operations more sustainable.FRT Machinerysupports this initiative by offering equipment that reduces energy consumption and minimizes waste. For instance, our leaching tanks are designed to recycle water and chemicals, reducing the overall environmental impact. Additionally, we continuously research and develop new technologies aimed at improving efficiency and sustainability across all stages of silver refining.

By following these steps and utilizing the latest technology provided byFRT Machinery, you can refine silver effectively while also contributing to a greener future. Each phase of the refining process plays a vital role in producing high-quality silver that meets stringent market demands.