What Is Refining Silver

Silver refining is a process that transforms raw or scrap silver into a purer form. This purification method is crucial for achieving the high purity levels required for industrial, commercial, and jewelry applications. FRT Machinery, a leading provider of silver refining solutions, explains the process and its importance.

Refining Silver: An Overview

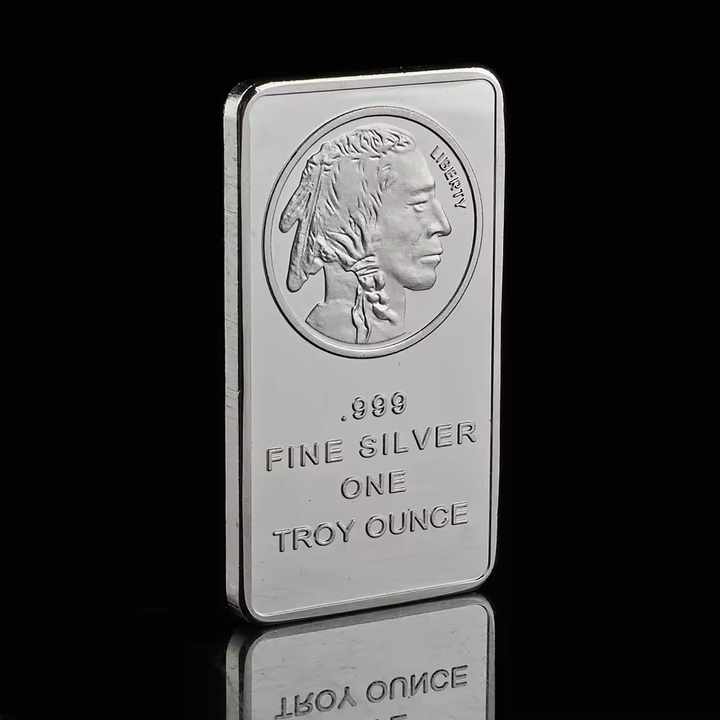

The first step in understanding how to refine silver is to grasp the concept of what refining actually entails. Refining silver involves removing impurities such as other metals or non-metallic substances from raw or recycled silver. This is done to increase the metal’s purity, which is essential for various uses. For instance, industrial-grade silver typically needs to be at least 99.9% pure, while jewelry-grade silver may require even higher purity levels.

The Methods of Refining Silver

There are several methods used in refining silver, each with its own advantages and disadvantages. One common method iselectrolytic refining, where silver is dissolved in a solution and then deposited onto a cathode. Another method isfire refining, which involves melting the silver and separating the impurities through a process called slagging. Both methods are effective, but the choice depends on the initial purity of the silver and the desired outcome.

Equipment Used in Refining Silver

High-quality refining requires specialized equipment designed to handle the chemical processes involved. FRT Machinery offers a range of equipment tailored for both electrolytic and fire refining processes. Their systems are designed to ensure maximum efficiency and safety during the refinement stages. Whether it’s furnaces for fire refining or tanks for electrolytic refining, FRT Machinery provides reliable solutions for every step of the process.

Benefits of Refining Silver

Refining silver not only increases its purity but also enhances its value and usability. Purer silver is more conductive, making it ideal for electrical components. It also has better luster, which is critical for jewelry and decorative items. Moreover, refined silver is easier to recycle, contributing positively to sustainability efforts within the industry.

Challenges in Refining Silver

Despite its benefits, silver refining faces several challenges. One major challenge is dealing with hazardous materials used in the refining process. Proper safety protocols must be implemented to protect workers and the environment. Another challenge is the energy consumption associated with refining processes, particularly in fire refining. Innovations in technology, however, are helping to mitigate these issues, making refining more efficient and eco-friendly.

Future Trends in Silver Refining

Looking ahead, the future of silver refining is likely to be shaped by technological advancements aimed at increasing efficiency and reducing environmental impact. FRT Machinery continues to invest in research and development to bring new technologies to market that will further streamline the refining process. These innovations promise not only to enhance the quality of refined silver but also to make the entire process more sustainable.

In conclusion, refining silver is a vital process that ensures the metal meets the high standards required by industries worldwide. By understanding the methods, equipment, and benefits associated with silver refining, one can appreciate the importance of this sophisticated procedure. As technology evolves, so too will the capabilities of refining, ensuring that silver remains a valuable resource for generations to come.