White Gold For Smelting

Understanding White Gold for Smelting: A Comprehensive Guide

White gold, a versatile alloy prized for its lustrous appearance and durability, finds extensive applications beyond jewelry making. In the industrial sector, particularly within smelting processes, white gold serves crucial roles due to its unique properties. FRT Machinery, a leader in manufacturing specialized equipment for metallurgical processes, explores the nuances of using white gold in smelting operations.

White Gold Alloys in Smelting Processes

The composition of white gold varies, typically consisting of gold mixed with alloys like silver, palladium, or nickel. These combinations impart specific characteristics that make it suitable for high-temperature environments encountered during smelting. FRT Machinery engineers designs that leverage these properties, enhancing the efficiency and longevity of smelting machinery.

Benefits of Using White Gold for Smelting

Incorporating white gold into smelting equipment offers several advantages. Its resistance to corrosion and wear ensures longer operational life cycles, reducing maintenance costs and downtime. Additionally, the alloy’s thermal conductivity facilitates better heat distribution, improving overall process efficiency. FRT Machinery integrates these benefits into their smelting solutions, ensuring optimal performance under extreme conditions.

Challenges and Considerations When Employing White Gold

While advantageous, integrating white gold into smelting processes isn’t without challenges. Cost considerations are significant due to the precious metals involved. Moreover, proper handling and processing techniques are essential to maintain the integrity of the alloy. FRT Machinery addresses these issues through innovative design and manufacturing practices, ensuring cost-effective and reliable smelting solutions.

Innovations in White Gold Smelting Equipment by FRT Machinery

Recognizing the potential of white gold in enhancing smelting operations, FRT Machinery has developed cutting-edge technologies. Their latest range of smelters utilizes advanced alloys, including white gold formulations, to achieve unparalleled efficiency and durability. This commitment to innovation positions FRT Machinery as a pioneer in the field, continuously pushing boundaries in metallurgical engineering.

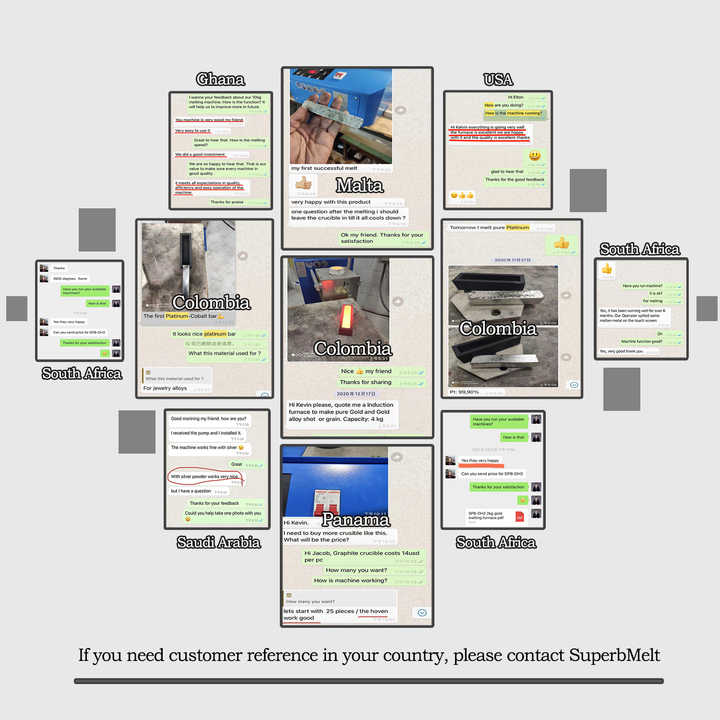

Case Studies: Real-World Applications of White Gold in Smelting

To illustrate the practical implications of using white gold in smelting, FRT Machinery shares insights from successful projects. These case studies highlight how incorporating this alloy can lead to substantial improvements in productivity and sustainability across various industries. By showcasing tangible outcomes, FRT Machinery demonstrates the real-world value of their approach to smelting technology.

Future Prospects for White Gold in Smelting Technologies

As research and development continue, the potential uses of white gold in smelting are expanding. FRT Machinery remains at the forefront of these advancements, exploring new alloys and techniques to enhance smelting capabilities. With a focus on sustainability and efficiency, the future looks bright for innovations driven by white gold applications in smelting.

By delving into the specifics of white gold usage in smelting, this article underscores the importance of choosing the right materials for industrial processes. FRT Machinery’s dedication to utilizing advanced alloys like white gold exemplifies their commitment to driving progress in the field of metallurgy.