cost of smelting silver

Understanding the Cost of Smelting Silver Key Factors and Considerations

The cost of smelting silver varies depending on several factors, including the scale of the operation, the type of equipment used, and additional materials required for the smelting process. Whether you’re smelting silver ore, scrap silver, or other forms of silver, understanding the costs involved is crucial for individuals and businesses alike. This article will explore the key factors that influence the cost of smelting silver and offer insights into how these costs are calculated.

What is Silver Smelting?

Silver smelting is the process of extracting pure silver from raw materials by applying high heat to separate it from other metals and impurities. The process involves melting the silver-containing material and using different methods to purify it, often with the help of chemicals or refining agents. Silver smelting is commonly used in both industrial applications and small-scale refining projects.

Primary Factors Affecting the Cost of Smelting Silver

The cost of smelting silver depends on various elements, ranging from equipment to energy consumption. Below are the primary factors that contribute to the overall expense of smelting silver.

1. Type of Silver Material

The type of silver material being smelted significantly impacts the cost. Smelting silver ore, for instance, can be more complex and expensive compared to refining scrap silver. Ore smelting often involves additional processes to extract silver from other minerals, whereas scrap silver is already in metallic form and may require fewer steps for purification.

2. Equipment Costs

The type and quality of equipment used for silver smelting are major factors in determining cost. Industrial furnaces, crucibles, and smelting pots all come with associated costs. More advanced smelting setups, such as electric induction furnaces, are more expensive upfront but offer greater precision and efficiency. For small-scale operations, lower-cost equipment such as propane furnaces and simple crucibles can help keep expenses manageable.

3. Energy Consumption

Smelting silver requires high temperatures, often exceeding 1,000 degrees Celsius (1,832 degrees Fahrenheit). As a result, energy consumption is a significant factor in the cost of smelting silver. Industrial smelting operations typically use large amounts of electricity or fuel to maintain these high temperatures, while smaller setups may rely on propane or natural gas. The energy costs will vary depending on the region, energy prices, and the type of furnace or heating equipment used.

4. Labor Costs

The expertise required to smelt silver can affect the overall cost of the process. Skilled workers are often needed to manage and operate the smelting equipment, monitor temperatures, and handle chemical processes. In industrial settings, labor costs can be substantial, especially if multiple workers or specialists are involved. On the other hand, small-scale smelting may be done by individuals with basic knowledge of the process, thus reducing labor costs.

5. Chemical and Refining Agents

Silver smelting may require the use of chemicals or flux agents to help remove impurities and separate silver from other metals. Commonly used materials include borax, soda ash, and charcoal. The cost of these chemicals adds to the overall expense of the smelting process, especially if high-purity silver is the goal.

6. Waste Management and Environmental Compliance

Proper disposal of waste materials generated during silver smelting is another factor that affects cost. Smelting silver can produce toxic byproducts, including fumes and slag, which must be safely managed to comply with environmental regulations. Businesses involved in silver smelting may need to invest in fume hoods, filtration systems, and waste disposal services, all of which contribute to the overall cost.

The Difference Between Large-Scale and Small-Scale Smelting

There is a significant difference between the cost of smelting silver on a large scale versus a small scale.

Large-Scale Smelting Operations

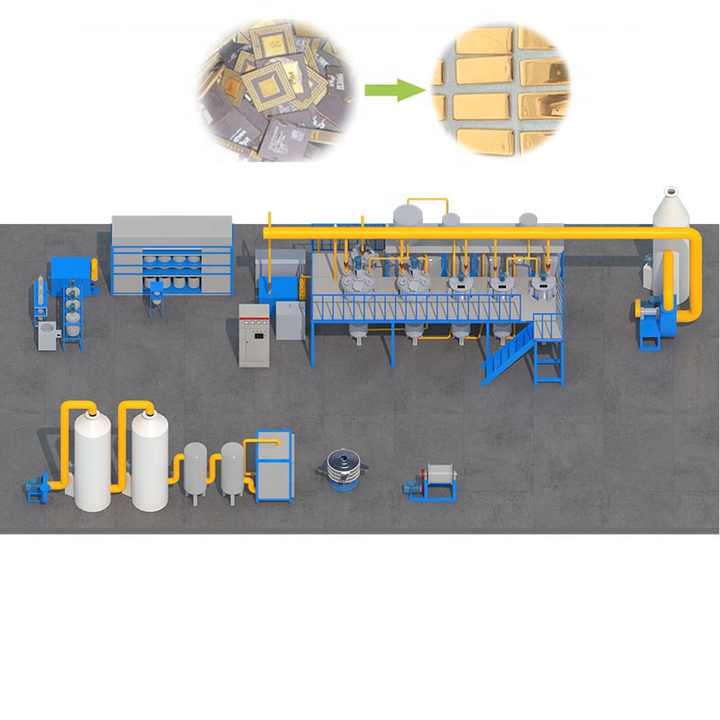

Large-scale silver smelting operations are typically carried out by mining companies or refineries that handle significant volumes of silver. These operations invest heavily in advanced equipment, including electric furnaces, cooling systems, and continuous refining machinery. While the upfront costs are high, large-scale operations benefit from economies of scale, allowing them to process large amounts of silver more efficiently. Energy consumption, labor, and equipment maintenance are major cost drivers in these settings.

Small-Scale and Home-Based Smelting

For those who wish to smelt silver at home or on a small scale, the cost can be significantly lower. Individuals can purchase affordable equipment, such as propane furnaces or crucibles, and handle smaller amounts of silver. However, even on a small scale, costs such as fuel and refining agents can add up. Small-scale smelting is ideal for refining scrap silver or small batches of ore but may not be cost-effective for large volumes.

How to Minimize the Cost of Smelting Silver

There are several strategies that can help reduce the cost of smelting silver, especially for those working on a smaller scale.

1. Invest in Energy-Efficient Equipment

Investing in energy-efficient furnaces or heating equipment can significantly lower the cost of smelting silver. Modern furnaces with precise temperature controls can reduce energy consumption, saving money in the long run.

2. Recycle Flux and Other Materials

In some cases, flux materials and other refining agents can be reused, helping to lower the cost of buying new chemicals for each smelting batch. Learning how to recycle these materials can reduce expenses without compromising the quality of the smelting process.

3. Smelt in Larger Batches

For those running small-scale smelting operations, processing larger batches of silver at once can help reduce energy costs and improve overall efficiency. Heating a larger quantity of material at a time minimizes the number of times the furnace needs to be fired up, reducing fuel consumption.

The cost of smelting silver is influenced by various factors, including the type of silver material, the equipment used, energy consumption, labor, and the need for chemicals or refining agents. While large-scale operations have higher upfront costs, they benefit from efficiency gains, whereas small-scale smelters may have lower costs but face limitations in terms of volume and efficiency. By understanding these factors, individuals and businesses can make informed decisions about how to manage the cost of smelting silver effectively.