crude gold smelting techniques

Crude Gold Smelting Techniques: An Overview

Gold smelting is the process of extracting pure gold from raw materials or impure gold ore. While modern gold refining techniques have advanced significantly, crude gold smelting techniques have been used for centuries and remain useful for small-scale miners, hobbyists, and remote gold recovery operations. In this article, we will explore the various crude gold smelting techniques used throughout history and today, highlighting the processes, tools, and methods involved.

What is Crude Gold Smelting?

Crude gold smelting is a process where heat is used to melt and separate gold from other elements, such as other metals, minerals, and impurities. The primary goal is to achieve a relatively pure form of gold, although the results may not be as refined as modern methods. Smelting is often used by miners and small-scale refiners who do not have access to advanced equipment or chemical methods for refining gold.

Common Crude Gold Smelting Techniques

Several crude gold smelting techniques have been used historically, with many still in use today by artisanal miners. These methods rely on basic equipment and materials that can be easily obtained.

1. Fire Smelting

One of the most traditional methods for smelting gold is through the use of fire. Fire smelting involves heating gold-bearing materials to high temperatures in a furnace or open fire to melt the gold and separate it from impurities. This method typically involves:

- Crushing the Ore: The gold-bearing ore is first crushed to break it into smaller pieces and expose the gold.

- Mixing with Flux: A flux, such as borax or sodium carbonate, is added to the ore to help separate the gold from impurities. The flux lowers the melting point of the materials, making the smelting process more efficient.

- Heating: The mixture is heated in a crucible or furnace until the gold melts. The impurities, known as slag, rise to the surface and are removed.

- Pouring: Once melted, the gold is poured into molds and allowed to cool, resulting in a gold ingot or bar.

While fire smelting can be effective for small amounts of gold, it requires high temperatures, which can be difficult to achieve without the right equipment.

2. Cupellation

Cupellation is an ancient method of refining gold, often used by early metallurgists to separate precious metals from base metals like lead. In this process, lead is used to extract gold from raw materials. The steps include:

- Preparation: Gold ore or scrap is mixed with lead or other base metals and placed in a special porous container called a cupel.

- Heating: The mixture is heated in a furnace at high temperatures, which causes the base metals to oxidize and be absorbed into the cupel.

- Gold Separation: As the base metals oxidize, the gold remains in a molten state and can be poured out or collected.

Cupellation is a relatively simple process that has been used for thousands of years, but it is primarily effective for small amounts of gold mixed with lead.

3. Miller Process (Simplified)

Although the full Miller process is an industrial refining method, some small-scale refiners use a simplified version for smelting gold. The process involves blowing chlorine gas through molten gold, which reacts with impurities like silver and base metals, separating them from the gold. The process is typically performed in small furnaces with limited equipment. Although it is more effective than traditional fire smelting, it still results in gold that is not as pure as more advanced methods.

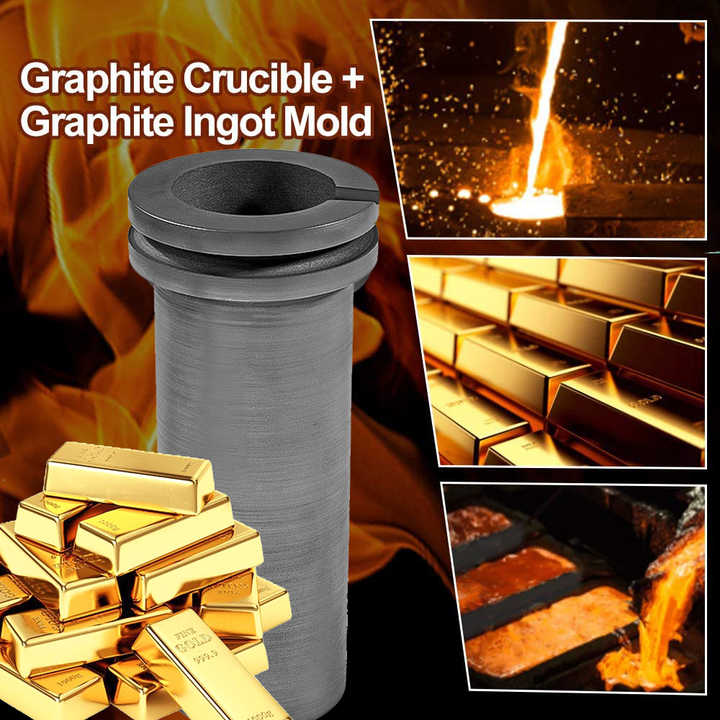

4. Crucible Smelting

Crucible smelting is another common method used for smelting gold, especially for those with access to small furnaces or high-quality crucibles. This method is particularly useful for hobbyists and small-scale miners. The steps involved include:

- Crushing and Mixing: Similar to fire smelting, the gold-bearing material is crushed and mixed with flux.

- Heating in a Crucible: The mixture is placed in a high-temperature crucible and heated until the gold melts.

- Pouring: The molten gold is poured into molds, leaving behind the impurities as slag, which can be discarded.

This method can produce relatively pure gold, although it still requires further refining to achieve commercial purity levels.

Advantages and Disadvantages of Crude Gold Smelting Techniques

Advantages:

- Accessibility: Crude smelting techniques can be performed with simple tools and materials, making them accessible to small-scale miners and hobbyists.

- Cost-Effective: These techniques are generally low-cost compared to modern refining methods, which require expensive chemicals and equipment.

- Historical Value: Some crude techniques, such as cupellation, have historical significance and are still used by researchers and enthusiasts interested in ancient metallurgical methods.

Disadvantages:

- Lower Purity: Crude smelting methods do not achieve the same level of purity as modern refining techniques. The gold produced often contains impurities, which must be removed through further refining.

- Limited Output: These techniques are typically only suitable for small quantities of gold, making them less practical for large-scale operations.

- Environmental Impact: Some methods, such as fire smelting, can release harmful fumes or cause deforestation if wood is used as a fuel source.

Modern Alternatives to Crude Gold Smelting

While crude gold smelting techniques are still in use today, many refiners have turned to more modern methods, such as:

- Aqua Regia: This chemical refining process uses a mixture of nitric acid and hydrochloric acid to dissolve gold, separating it from other materials. It produces high-purity gold but requires careful handling of dangerous chemicals.

- Electrolysis: This method uses electricity to purify gold by separating it from impurities in a solution. It is widely used in large-scale gold refining operations.

- Induction Furnaces: Modern induction furnaces allow for precise temperature control and are more efficient than traditional fire smelting techniques.

Crude gold smelting techniques have been used for centuries and continue to be useful for small-scale gold recovery operations. Whether through fire smelting, cupellation, or crucible smelting, these methods provide accessible and cost-effective ways to extract gold from ore or scrap materials. While they may not produce the highest purity levels, crude smelting remains an important part of gold refining history and small-scale gold production today.