current silver smelting prices usa

Understanding Current Silver Smelting Prices in the USA

The silver smelting industry in the USA plays a vital role in converting raw silver materials, such as ore and scrap, into usable forms for industries like jewelry making, electronics, and investment-grade bullion. Understanding the current silver smelting prices in the USA can help businesses and individuals make informed decisions when selling or refining silver. Prices fluctuate based on various market factors, including silver’s spot price, labor costs, and the complexity of the smelting process. This article will explore these aspects to give an overview of the current silver smelting prices in the USA.

The Role of Silver Smelting in the Refining Process

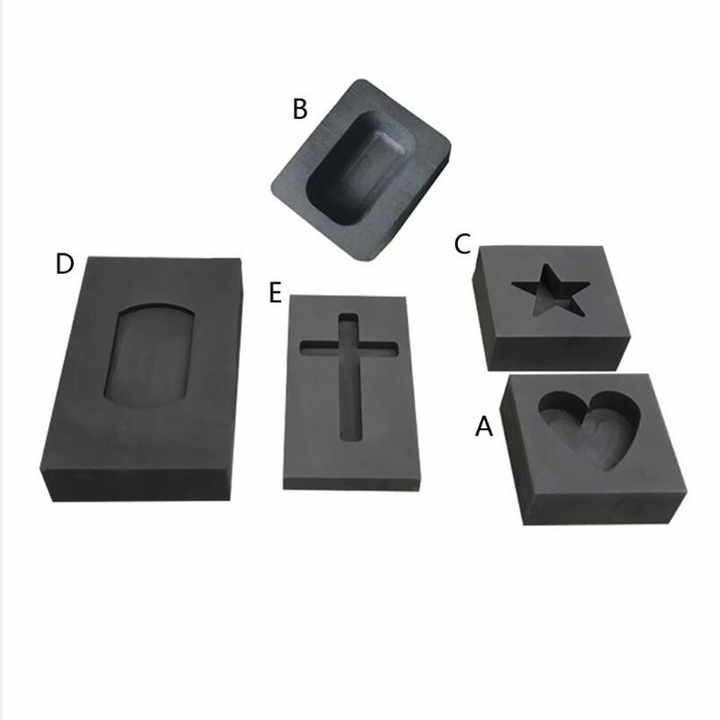

Silver smelting is a crucial part of the refining process, where raw silver is heated and separated from impurities. The process is typically applied to silver ore, scrap silver, or silver-bearing materials. Smelting involves high temperatures, which break down the material and separate pure silver from other elements. Once the silver is extracted, it can be cast into ingots, bars, or other forms, ready for further refining or sale.

Factors That Influence Silver Smelting Prices

Several factors influence the cost of silver smelting in the USA. These variables cause prices to change frequently, so it’s important to consider each of them when evaluating current smelting rates.

1. Spot Price of Silver

One of the most significant factors affecting silver smelting prices is the current spot price of silver. The spot price is the current market price at which silver can be bought or sold for immediate delivery. As of 2024, the price of silver has experienced volatility due to global economic conditions, supply, and demand. When the spot price of silver rises, smelting companies may charge higher fees to account for the increased value of the metal they process.

2. Type of Material Being Smelted

The cost to smelt silver depends on the type of material being processed. For example, smelting silver ore may require more complex machinery and refining techniques compared to melting down scrap silver. Scrap silver, such as old jewelry or industrial waste, often contains fewer impurities and can be processed more easily, resulting in lower smelting costs.

3. Smelting Facility and Equipment

The type of smelting facility used can also impact prices. Large-scale industrial smelting operations often benefit from economies of scale, which can result in lower costs per ounce of silver processed. However, smaller or specialized smelting services may charge higher rates due to the customized nature of their operations or the need for more advanced equipment.

4. Labor and Overhead Costs

Labor costs in the USA are higher than in some other regions, contributing to increased smelting prices. Additionally, overhead costs such as energy, regulatory compliance, and waste management also influence the price of smelting silver. Facilities located in areas with higher energy prices, for example, may charge more for their services to offset these costs.

5. Purity and Quality of Silver

The desired purity level of the refined silver will also affect smelting costs. Higher purity levels require more precise refining techniques, which can increase the overall cost. Smelting companies often charge based on the percentage of pure silver extracted from the raw material, meaning lower-quality silver ore or scrap with many impurities may incur higher fees.

Current Silver Smelting Prices in the USA

As of 2024, silver smelting prices in the USA typically range between $1 to $5 per ounce of silver processed. This estimate depends on several factors, including the type of material being smelted and the scale of the operation. Some industrial smelters may offer lower per-ounce prices for bulk processing, while smaller-scale operations or specialized services may charge higher fees.

For scrap silver, where the process is generally simpler, smelting fees tend to be on the lower end of the spectrum. On the other hand, smelting silver ore, which requires additional steps to extract the silver from its raw mineral form, may fall on the higher end of the pricing range.

Regional Differences in Smelting Prices

Prices for silver smelting can vary by region within the USA due to differences in local energy costs, environmental regulations, and the availability of smelting services. For example:

- West Coast: Smelting facilities on the West Coast, particularly in states like California, may charge higher prices due to stricter environmental regulations and higher labor costs.

- Midwest: In regions with more abundant industrial resources, such as the Midwest, smelting prices may be lower due to greater competition and lower operational costs.

- Northeast: Facilities in the Northeast may offer competitive prices, but urban centers may face higher energy costs, which can raise smelting fees.

Trends Affecting Smelting Prices in 2024

Several trends are currently affecting silver smelting prices in the USA:

- Rising Energy Costs: Increasing energy prices across the USA are driving up the cost of operating smelting furnaces, leading to higher smelting fees. This is particularly noticeable in states with higher electricity or natural gas prices.

- Increased Demand for Silver: As the demand for silver in industrial applications like electronics, solar panels, and medical devices grows, the market for refining and smelting silver has also expanded. Increased demand may lead to higher smelting prices as facilities work to keep up with processing needs.

- Environmental Regulations: Stricter environmental standards and waste management regulations can increase operating costs for smelting facilities, particularly those dealing with hazardous byproducts. This often results in higher fees for smelting services, especially in regions with stringent environmental laws.

Understanding the current silver smelting prices in the USA requires consideration of multiple factors, including the spot price of silver, the type of material being processed, and regional differences in labor and overhead costs. As silver prices fluctuate in the global market, smelting fees also tend to rise and fall accordingly. For those looking to smelt silver, whether on an industrial scale or for smaller projects, staying informed about these price drivers can help in making cost-effective decisions.