process of gold purification

Gold has long been cherished for its beauty and value, but the process of gold purification is essential to unlock its full potential. This process involves several methods and techniques designed to refine gold from its raw state into a highly pure metal. Understanding the process of gold purification helps in appreciating the complexities involved in achieving gold of the highest quality.

Traditional Methods in the Process of Gold Purification

Historically, the process of gold purification began with the simplest methods. One of the earliest techniques is fire assay, which involves heating gold ore with a flux to separate gold from other materials. This process of gold purification has been used for centuries and is effective at producing a relatively high purity of gold. The flux combines with impurities to form a slag that is removed, leaving behind the pure gold.

Another traditional method in the process of gold purification is mercury amalgamation. This technique involves mixing gold ore with mercury to form an amalgam. The gold is then separated from the mercury through heating, after which the mercury evaporates, leaving behind purified gold. While effective, this method poses significant environmental risks due to mercury pollution.

Modern Techniques for the Process of Gold Purification

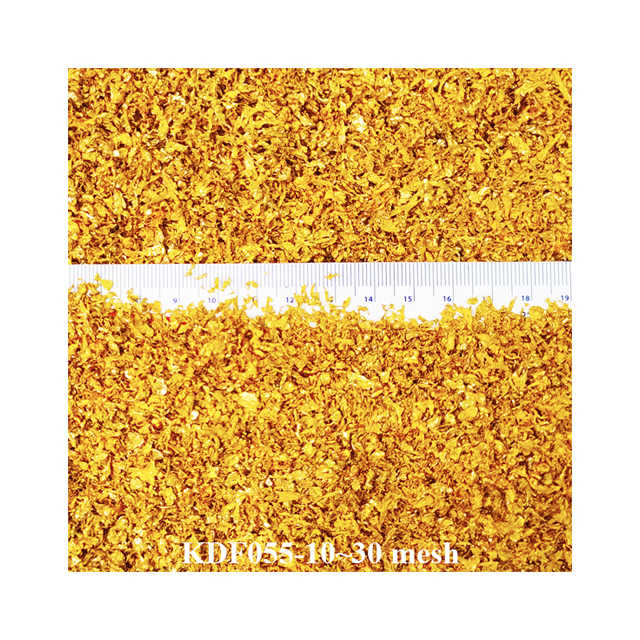

With advancements in technology, the process of gold purification has evolved to include more sophisticated methods. One of the most prominent modern techniques is cyanide leaching. In this process, gold ore is treated with a cyanide solution, which dissolves the gold from the ore. The gold is then recovered from the cyanide solution through precipitation or adsorption onto activated carbon. This method is particularly useful for extracting gold from low-grade ores and is known for its high efficiency.

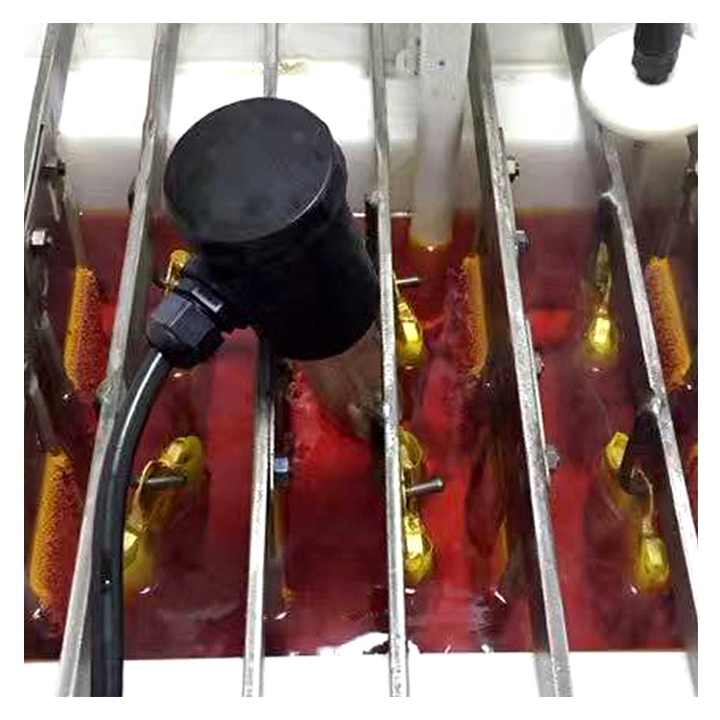

Electrolytic Refining is another contemporary method in the process of gold purification. This technique involves dissolving gold in an electrolyte solution and then depositing it onto an electrode. The gold obtained through electrolytic refining is typically of very high purity. This method is favored for its precision and the quality of gold it produces.

Innovations and Sustainability in the Process of Gold Purification

As awareness of environmental issues grows, the process of gold purification is adapting to include more sustainable practices. Traditional methods like mercury amalgamation have significant environmental drawbacks, including mercury contamination. Modern techniques, such as cyanide leaching, also raise concerns about chemical handling and environmental impact.

In response, there have been efforts to innovate and improve the process of gold purification to minimize environmental impact. Bioleaching is one such innovation, where bacteria are used to extract gold from ores. This method is more environmentally friendly and offers a sustainable alternative to traditional processes.

Green Chemistry is another approach being explored in the process of gold purification. By utilizing less toxic chemicals and developing more efficient methods, green chemistry aims to reduce the environmental footprint of gold refining.

The process of gold purification is a complex and multifaceted endeavor that has evolved significantly over time. From traditional methods like fire assay and mercury amalgamation to modern techniques such as cyanide leaching and electrolytic refining, each method has its own strengths and limitations. As the industry continues to advance, there is a growing emphasis on developing sustainable and environmentally friendly practices in the process of gold purification. These innovations aim to achieve the highest purity of gold while addressing the environmental concerns associated with traditional methods.