the process of gold purification

Gold is one of the most sought-after precious metals, valued for its beauty and rarity. However, gold in its natural state often contains impurities that reduce its value and usefulness. The process of gold purification is essential to remove these impurities and produce pure gold suitable for various applications, from jewelry making to investment purposes. In this article, we will explore the various methods involved in the process of gold purification, shedding light on both traditional and modern techniques.

What is the Process of Gold Purification?

The process of gold purification involves refining gold to remove impurities such as other metals, minerals, and non-metallic inclusions. This process can be carried out using a variety of techniques, each with its own advantages and limitations. The primary goal is to achieve the highest possible purity level, typically 99.5% to 99.99%, depending on the intended use of the gold.

Gold purification is not only about enhancing the metal’s appearance but also about improving its properties for industrial and commercial use. Pure gold is more malleable, ductile, and resistant to corrosion, making it ideal for creating high-quality products.

Traditional Methods in the Process of Gold Purification

The process of gold purification has been practiced for thousands of years, with ancient civilizations developing various methods to refine gold. Some of the traditional techniques include:

- Cupellation: This method involves melting gold in a furnace with a porous cupel, usually made of bone ash. The impurities, such as lead, are absorbed by the cupel, leaving behind pure gold. Cupellation is one of the oldest known methods of gold purification and is still used today for small-scale refining.

- Amalgamation: In this process, mercury is used to extract gold from its ore. The mercury forms an amalgam with the gold, which is then heated to evaporate the mercury, leaving behind purified gold. Although effective, this method is less common today due to the toxic nature of mercury.

- Miller Process: Developed in the 19th century, the Miller process involves blowing chlorine gas through molten gold to separate impurities. The impurities form a chloride slag on the surface, which can be removed, leaving behind high-purity gold.

Modern Techniques in the Process of Gold Purification

While traditional methods are still used, modern technology has introduced more efficient and environmentally friendly techniques for the process of gold purification. Some of these methods include:

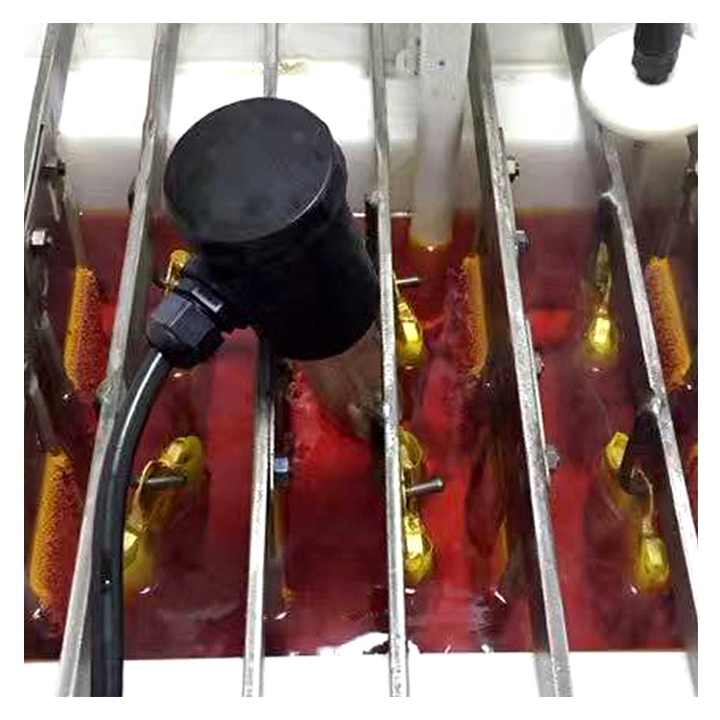

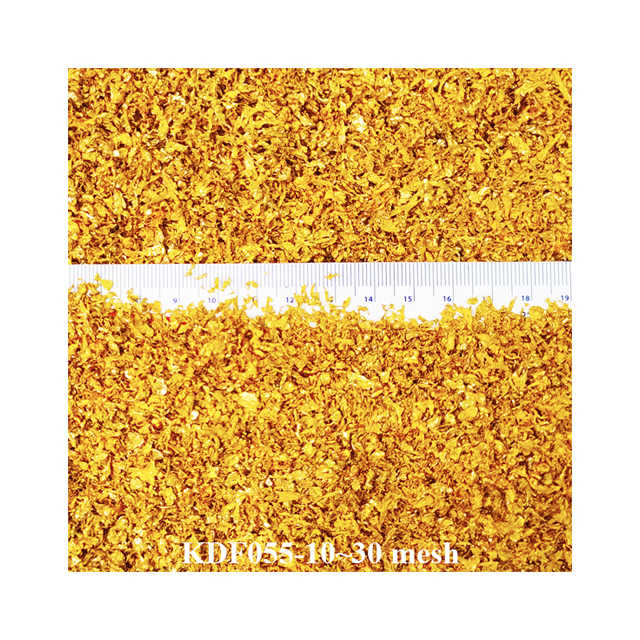

- Electrolytic Refining: This process uses electrolysis to purify gold. The impure gold is made the anode in an electrolytic cell, while pure gold is deposited on the cathode. The electrolyte is usually a solution of gold chloride. This method can achieve very high purity levels, making it a popular choice for industrial applications.

- Aqua Regia Process: Aqua regia, a mixture of hydrochloric acid and nitric acid, is used to dissolve gold and separate it from impurities. The solution is then treated to precipitate pure gold. This process is highly effective but requires careful handling due to the corrosive nature of aqua regia.

- Wohlwill Process: An improvement on the Miller process, the Wohlwill process also uses electrolysis but with a different electrolyte, resulting in gold of even higher purity. This method is often used to produce gold that is 99.99% pure, commonly referred to as “four nines” gold.

The Environmental Impact of the Process of Gold Purification

The process of gold purification can have significant environmental impacts, especially when using traditional methods that involve toxic chemicals like mercury and cyanide. These substances can contaminate soil and water, posing risks to ecosystems and human health.

Modern techniques aim to minimize these impacts by using safer chemicals and recycling waste products. For example, the electrolytic refining process produces fewer harmful byproducts, and some methods allow for the recovery and reuse of chemicals.

Applications of Purified Gold

Once the process of gold purification is complete, the purified gold can be used in various applications. These include:

- Jewelry Making: Pure gold is highly prized in the jewelry industry for its luster and resistance to tarnish. Gold purified through advanced techniques ensures the highest quality jewelry.

- Electronics: Gold’s excellent conductivity and resistance to corrosion make it ideal for use in electronic components, such as connectors and switches.

- Investment: Purified gold is often minted into coins or bars for investment purposes. High-purity gold is preferred by investors seeking to store wealth in a stable, tangible asset.

- Medical Applications: Gold is used in various medical applications, including dental work and cancer treatment. Its biocompatibility and resistance to bacteria make it valuable in these fields.

The process of gold purification is a crucial step in transforming raw gold into a valuable and versatile material. Whether using ancient methods like cupellation or modern techniques like electrolytic refining, the goal remains the same: to produce pure gold that meets the highest standards of quality. As technology advances, the process of gold purification continues to evolve, offering new opportunities to refine gold more efficiently and with less environmental impact.