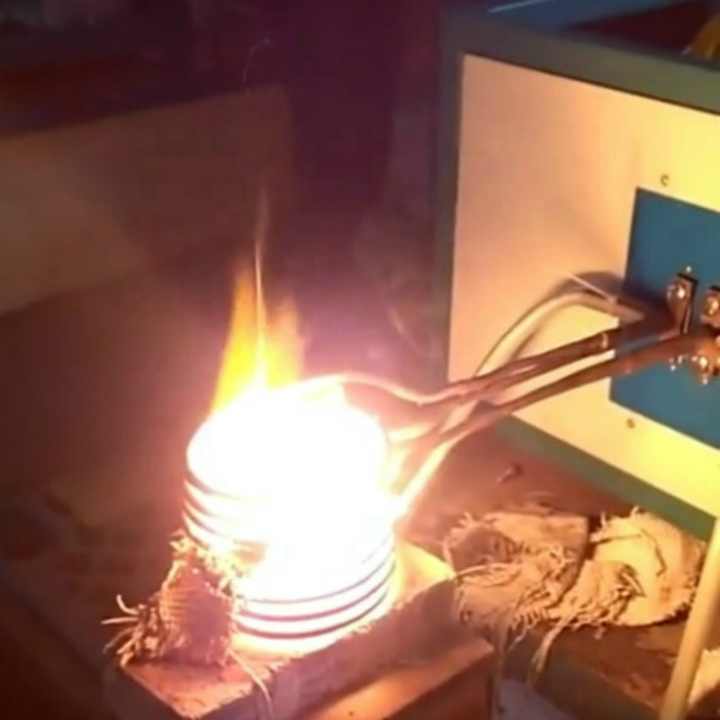

process of refining gold by fire

The Process of Refining Gold by Fire

Refining gold by fire is a traditional and widely used method for purifying gold, especially in artisanal and small-scale mining operations. This technique employs high temperatures to separate gold from impurities, resulting in higher purity levels. This article explores the process of refining gold by fire, its steps, benefits, and considerations.

Understanding Gold Refining by Fire

Gold refining by fire, often referred to as fire assaying or smelting, utilizes intense heat to melt gold and separate it from other metals and minerals. This method is particularly effective for purifying gold obtained from ores or recycled materials. By applying heat, impurities are removed, allowing for the recovery of high-quality gold.

Steps in the Gold Refining Process by Fire

Preparation of Materials

Before the refining process begins, the gold-bearing material must be prepared. This involves crushing and grinding the ore or scrap gold to increase the surface area. The smaller the particles, the more efficient the refining process will be. Additionally, fluxes may be added to aid in the separation of gold from impurities.

Melting

The next step is melting the prepared gold material. This is typically done in a furnace capable of reaching high temperatures, often exceeding 1,060 degrees Celsius (1,940 degrees Fahrenheit). The gold melts, and its density allows it to settle at the bottom of the crucible, while lighter impurities rise to the surface.

Adding Fluxes

Fluxes such as borax, sodium carbonate, or potassium nitrate are commonly added during the melting process. These substances help to bind with impurities and create a slag that can be easily removed. Fluxes lower the melting point of the materials and facilitate the separation of gold from other metals.

Separation of Gold and Slag

Once the gold is melted and the flux has been added, the next step is to allow the mixture to cool slightly. As it cools, the slag, containing impurities, will solidify and can be skimmed off the top. The purified gold, now in liquid form, can be poured into molds to cool and solidify.

Refining High-Purity Gold

After the initial refining process, the gold may still contain small amounts of impurities. To achieve higher purity levels, further refining may be necessary. This can involve additional melting and the use of chemicals such as nitric acid or aqua regia to dissolve remaining impurities. The gold is then precipitated out of solution, resulting in nearly pure gold.

Benefits of Fire Refining

Efficiency

Refining gold by fire is a relatively efficient method for purifying gold. The high temperatures allow for the effective separation of gold from impurities, leading to high recovery rates.

Accessibility

This method is accessible to small-scale miners and artisans who may not have access to advanced refining technologies. The equipment needed for fire refining, such as a furnace and crucibles, is often easier to obtain and operate.

Considerations in Fire Refining

Safety Precautions

Working with high temperatures and potentially hazardous materials requires strict safety measures. Proper protective equipment, ventilation, and training are essential to minimize risks associated with heat and fumes.

Environmental Impact

While fire refining is effective, it can produce emissions and waste that may impact the environment. It is important to adopt practices that reduce the environmental footprint of the refining process, such as managing waste materials and emissions.

The process of refining gold by fire is a time-honored method that effectively purifies gold through the application of high temperatures. With its combination of efficiency and accessibility, this technique remains popular among artisanal miners and small-scale operations. By understanding the steps involved and adhering to safety and environmental considerations, gold refining by fire can continue to be a valuable method for obtaining high-quality gold.