Smelting Silver And Gold For Jewelry

Smelting Silver and Gold for Jewelry: Precision and Artistry

FRT Machinery: Enhancing the Process of Smelting Silver for Jewelry

Smelting silver and gold is an ancient craft that has evolved over millennia. Today, with the advent of modern technology, the process has become more efficient and precise. FRT Machinery, a leading manufacturer of smelting equipment, offers state-of-the-art solutions designed to meet the demands of contemporary jewelry making.

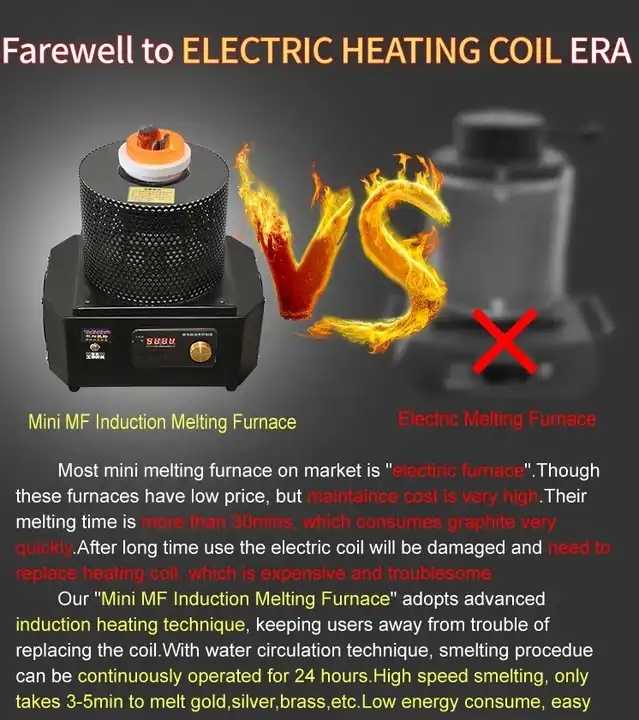

One key aspect of smelting silver involves heating the metal to its melting point, which is around 962°F (516°C). This requires specialized furnaces capable of reaching and maintaining these high temperatures without compromising the integrity of the metal. FRT Machinery’s furnaces are built with advanced insulation materials and precise temperature control systems, ensuring uniform heat distribution and minimal energy consumption.

The Role of FRT Machinery in Smelting Gold for Jewelry Crafting

Gold, with its higher melting point of approximately 1,943°F (1,062°C), presents unique challenges when it comes to smelting. To achieve the best results, goldsmiths rely on robust machinery that can handle the intense heat while also providing fine control over the smelting process. FRT Machinery’s gold smelting equipment is engineered to deliver both power and precision, making it an indispensable tool for artisans and large-scale manufacturers alike.

In addition to high-temperature capabilities, FRT Machinery’s systems incorporate features such as automatic slag removal and alloying capabilities, which are crucial for producing high-quality gold pieces. These features help in refining the metal by separating impurities and creating alloys with specific properties tailored to different jewelry applications.

Advanced Techniques in Smelting Silver and Gold for Jewelry Using FRT Machinery

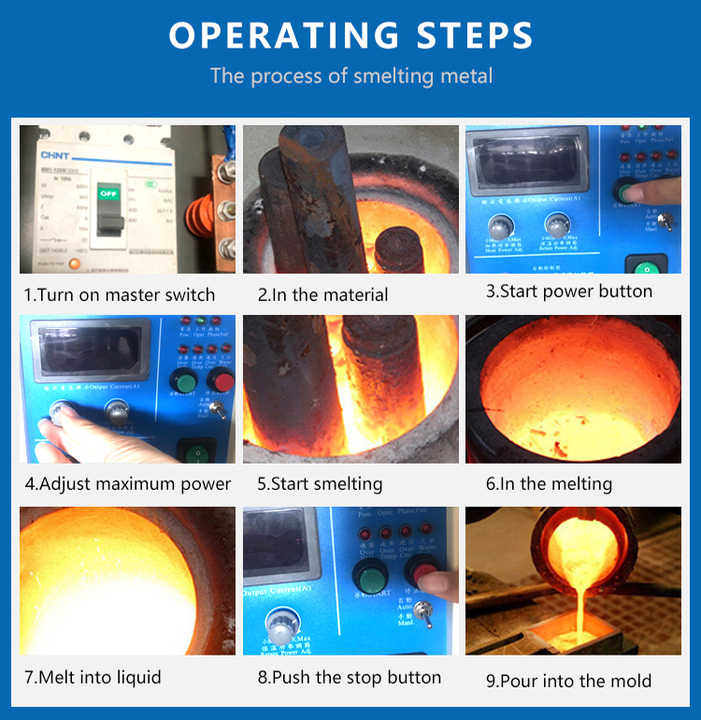

Advanced smelting techniques have revolutionized how silver and gold are processed for jewelry creation. By integrating automation and digital controls, FRT Machinery enables jewelers to achieve consistent results every time. The company’s equipment supports processes like casting, where molten metal is poured into molds to form intricate designs; this method requires precise temperature management and timing to ensure the right consistency of the metal.

Moreover, FRT Machinery provides training and support to help users get the most out of their machines. This includes guidance on optimizing settings for different metals and alloys, as well as tips for maintaining the equipment to ensure longevity and reliability.

Sustainability in Smelting Silver and Gold for Jewelry with FRT Machinery

As environmental concerns grow within the industry, there is a growing emphasis on sustainable practices. FRT Machinery addresses this need through innovations that reduce energy consumption and minimize waste during the smelting process. For instance, their furnaces utilize energy-efficient designs that lower operational costs while reducing carbon footprints.

Furthermore, FRT Machinery promotes recycling of precious metals by offering solutions that facilitate the recovery and reuse of scrap material. This not only helps conserve natural resources but also provides economic benefits to businesses looking to streamline their operations and improve profitability.

Conclusion: Elevating Jewelry Craftsmanship Through Innovative Smelting Solutions from FRT Machinery

The art of smelting silver and gold continues to evolve, driven by technological advancements and changing market demands. FRT Machinery stands at the forefront of this evolution, providing innovative tools that empower jewelry makers to push boundaries and create exquisite works of art. Whether you’re a small artisan workshop or a large production facility, investing in FRT Machinery’s smelting solutions can transform your workflow, enhancing both efficiency and creativity in your craft.