Smelting Silver Ore Process

Smelting Silver Ore: A Comprehensive Guide to Transforming Raw Materials into Precious Metals

Understanding the Basics of Silver Smelting

Silver smelting is a complex process that requires precision and expertise. It involves extracting silver from its ore using high temperatures and chemical reactions. This process has been used for centuries, evolving over time to become more efficient and environmentally friendly. At FRT Machinery, we specialize in providing state-of-the-art equipment designed specifically for smelting silver ore, ensuring optimal results while minimizing environmental impact.

Preparing Silver Ore for Smelting

Before smelting can begin, silver ore must undergo preparation. This includes crushing and grinding the ore to reduce it to a fine powder. The finer the particles, the easier it is to extract the silver. Our advanced grinding mills at FRT Machinery are engineered to achieve the necessary particle size efficiently, preparing the silver ore perfectly for the next steps in the smelting process.

The Role of Fluxes in Silver Smelting

Fluxes play a critical role in the smelting of silver ore. They help to remove impurities by forming a slag layer on top of the molten metal. This allows the silver to separate cleanly from unwanted materials. FRT Machinery offers specialized flux additives that enhance the smelting process, ensuring that the resulting silver is of the highest purity.

Implementing Safety Measures During Silver Smelting

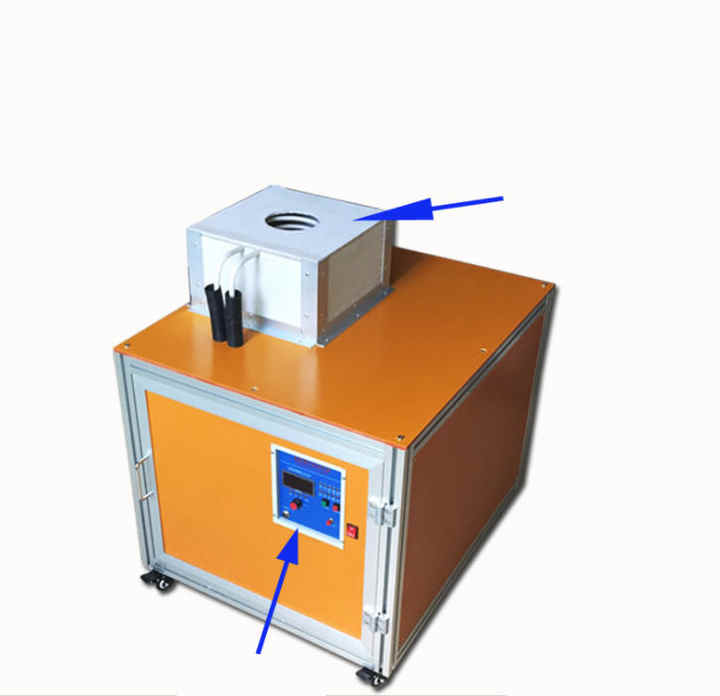

Safety is paramount during the smelting of silver ore. High temperatures and potentially hazardous chemicals require strict adherence to safety protocols. FRT Machinery designs its smelting equipment with built-in safety features, such as emergency shut-off systems and temperature controls, to protect operators and maintain operational integrity.

Utilizing Energy-Efficient Techniques for Smelting Silver Ore

Energy efficiency is crucial in smelting operations, not only to reduce costs but also to minimize environmental impact. FRT Machinery’s smelting furnaces are designed with energy conservation in mind, employing advanced insulation and heat recovery systems. These innovations ensure that every kilowatt of energy is utilized effectively, making the process of smelting silver ore both economical and sustainable.

Post-Smelting Processing of Silver

After smelting, the silver must be refined further to achieve the desired purity levels. This often involves additional heating and chemical treatments. FRT Machinery provides comprehensive post-smelting solutions, including refining furnaces and purification systems, which are essential for producing silver of exceptional quality.

Advantages of Using FRT Machinery for Your Silver Smelting Needs

Choosing FRT Machinery for your silver smelting needs means investing in reliability, efficiency, and innovation. Our equipment is designed to meet the stringent demands of modern smelting processes, offering unparalleled performance and durability. Whether you’re a small-scale operation or a large industrial facility, FRT Machinery has the right tools to optimize your silver smelting process, ensuring high yields and superior product quality.